Troubleshooting John Deere 5525 issues requires a seasoned approach, as this series of tractors is a staple in agricultural machinery and demands regular maintenance. Hydraulic problems often top the list, with farmers regularly facing complications related to the three-point hitch — a critical component for various implements. In our comprehensive guide, we delve into the nuances of John Deere tractor repairs, shining a light on how to diagnose and resolve common hydraulic setbacks to keep your farm running smoothly.

Understanding the intricacies of these tractors’ hydraulic systems not only ensures operational efficiency but also secures the longevity of the equipment. Whether you’re confronting a hitch that won’t lift or experiencing slow descent rates, our expert insights into John Deere maintenance practices present clear, methodical solutions. We’ll navigate you through potential fluid levels anomalies, filter blockages, and fitting adjustments critical to rectify any operational hitches.

Key Takeaways

- Identify and troubleshoot hydraulic issues in your John Deere 5525 for optimal performance.

- Learn the signs that indicate your three-point hitch needs attention and the step-by-step solutions.

- Dive into the reasons behind hydraulic failures and get practical John Deere tractor repair advice.

- Understand the necessity of routine John Deere maintenance to avoid long-term damage.

- Explore reliable techniques to maintain your tractor’s hydraulic system integrity and functionality.

Understanding John Deere 5525 Hydraulic and Transmission Issues

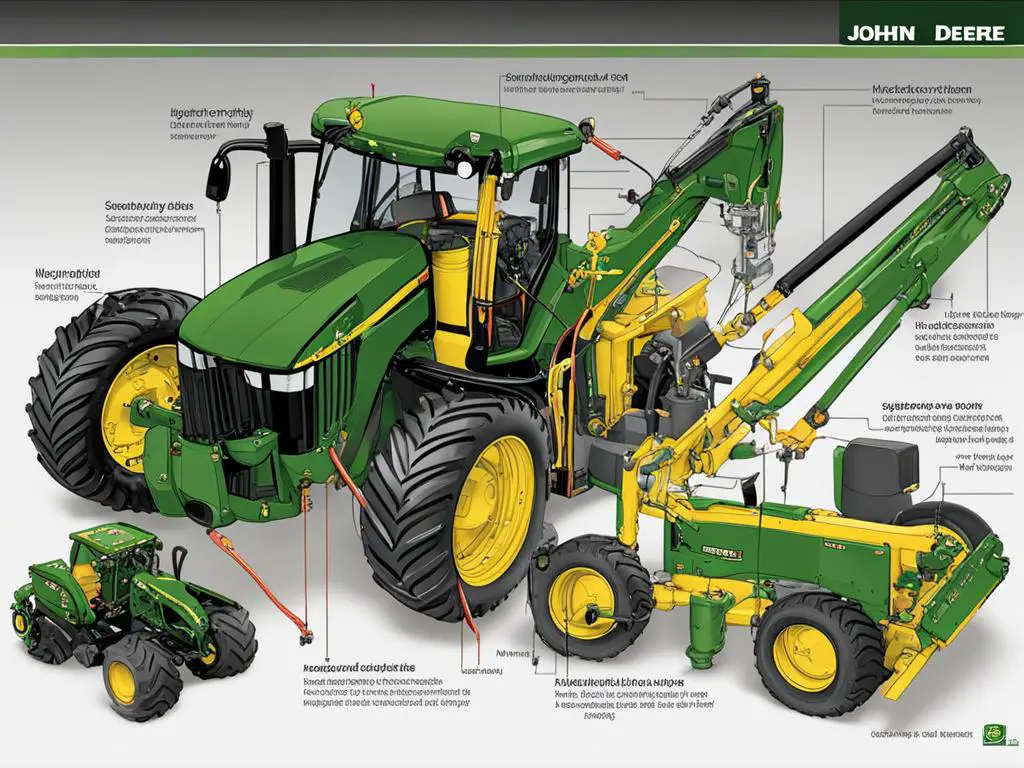

Owners of the John Deere 5525 tractor are often confronted with hydraulic system challenges that can disrupt daily operations. Among these, the tractor’s three-point hitch plays a pivotal role in attachment and lift functionalities, which when compromised, point towards underlying hydraulic problems. Here we explore the facets of such issues, including tractor hitch issues and hydraulic pump failure, that frequently ail this robust agricultural machinery.

Typically, the heart of these hitch complications lies in the hydraulic pump, control lever, and control valve. The pump, a primary mover in this system, generates the vital pressure that operates the hitch, enabling the tractor to perform its tasks efficiently. However, problems like insufficient fluid levels, clogged filters, or the use of incorrect fluid types can throw a wrench in the works, leading to inadequate hydraulic performance or complete failure.

Furthermore, the control valves, which are intricately connected to the hydraulic lift control lever, are significant in modulating the hitch’s ascent and descent. Overseeing the flow of hydraulic fluid, these valves can become a point of failure if not properly maintained. Alongside this, a selective speed control valve governs the rate at which the hitch lowers, adding another layer of complexity to the troubleshooting process.

To determine the root cause of hydraulic pump failure or related issues, a comprehensive inspection of the hydraulic system is necessary. This includes but is not limited to examining all connections for snugness, ensuring the hydraulic fluid is at the appropriate level and of the correct specification, and verifying the integrity of all filters involved.

Some common symptoms that may be encountered include the hitch failing to maintain its position (either not lifting or descending too slowly), as well as inability to lower once raised. These symptoms often tie back to either an external control mismatch or an internal mechanical failure. In cases where basic troubleshooting doesn’t yield results, it might become necessary to delve into the tractor’s rear end. This step typically involves a thorough disassembly to replace seals, O-rings, or lift pistons affected by rust or other contaminants.

Presented below is a detailed troubleshooting guide that helps to diagnose various scenarios you might encounter with your tractor’s hydraulic system. For owners and operators of the John Deere 5525, understanding these nuances can lead to efficient identification and application of necessary repair solutions to maintain the tractor’s operability.

- Three-Point Hitch Will Not Stay Up or Leaks Down: Check fluid levels, filter conditions, and selective control valve.

- Hitch Won’t Lift: Inspect the hydraulic pump functionality and control handle connections.

- Hitch Descends Too Slowly: Investigate speed control valve and look for potential blockages.

- Hitch Fails to Lower: Check for mechanical binding inside the lift piston or shaft mechanism.

| Problem | Possible Cause | Solution |

|---|---|---|

| Hitch Won’t Stay Up | Hydraulic Fluid Leak | Replace seals or O-rings |

| No Lift Functionality | Hydraulic Pump Failure | Service or replace the pump |

| Slow Descent | Control Valve Issue | Clean or replace speed control valve |

| Hitch Won’t Lower | Mechanical Binding | Disassemble and inspect lift piston and shaft |

It’s crucial to note that while some tractor parts can be serviced by the user, other more complex repair solutions may require the expertise of a professional technician or an authorized John Deere service center. Always refer to your tractor’s service manual for specific maintenance tasks or when delving into the hydraulic system, as precision and experience are paramount for a successful repair.

John Deere 5525 Problems and Preventive Maintenance

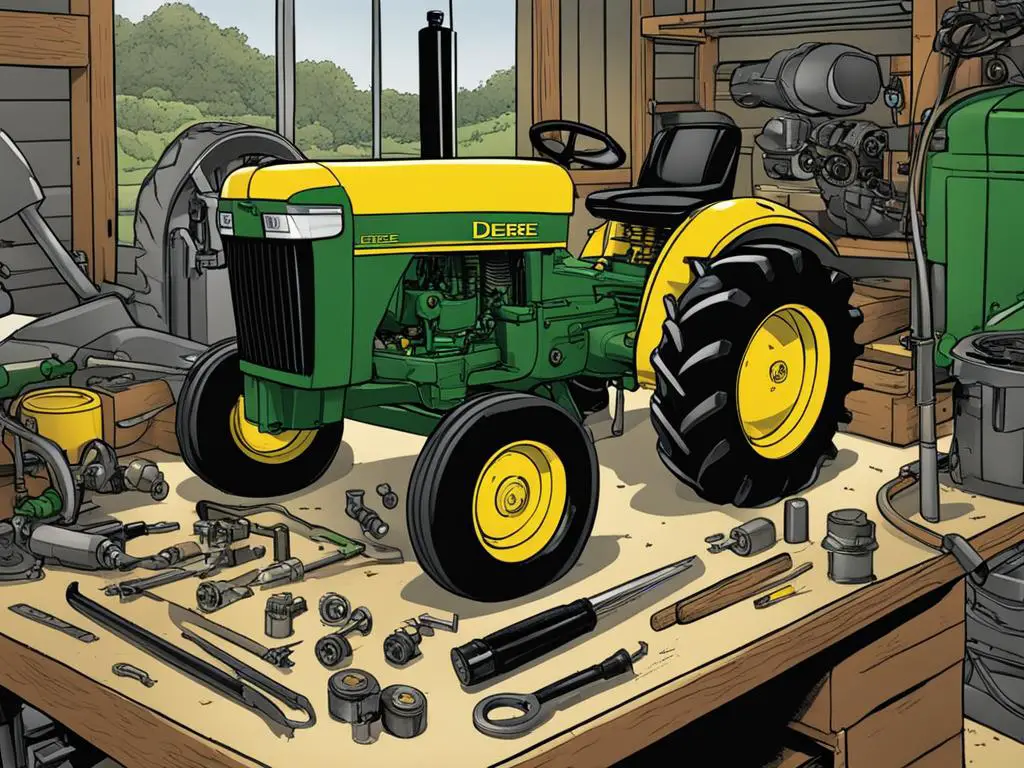

Maintaining a John Deere 5525 tractor is key to ensuring optimal performance and longevity. A well-executed maintenance routine includes regular inspections and the replacement of various filters at appropriate service intervals. This not only keeps the tractor running smoothly but also helps in early detection and prevention of potential issues. Sticking to the John Deere maintenance schedule is a critical part of effective tractor servicing.

Hydraulic/Transmission Oil Filter Maintenance

One of the primary aspects of maintaining your tractor’s hydraulic system is the hydraulic oil filter replacement. For the 5525 series, it’s recommended to replace this filter after the initial 100 hours and subsequently every 600 hours. Staying on top of this oil filter service interval helps ensure that your tractor’s hydraulic and transmission systems remain free from contaminants, which could cause damage or inefficiency over time.

Cab Filter Cleaning Schedule

Cab air quality is vital for operator comfort and health. This makes cab air filter cleaning an important part of the John Deere maintenance routine. Both the recirculation and fresh tractor cabin filters should be cleaned after every 300 hours of operation. Consistent maintenance of these filters guarantees proper air circulation, keeping the cabin environment clean and safe.

Engine Oil and Fuel Filter Replacement

An engine oil filter change is crucial for maintaining John Deere engine health. Depending on your model, you will need to replace the engine oil filter either after 300 hours or after the first 100 hours and, thereafter, every 450 hours or annually if using John Deere Plus-50 oil. Similarly, fuel filter maintenance should be conducted after every 300 hours to protect the engine from impurities and ensure efficient operation.

Air Filter Servicing for Optimal Performance

To support John Deere engine care, attention to air filter maintenance is non-negotiable. The primary air filter should be cleaned every 300 hours and replaced every 1800 hours or yearly. The secondary air filter follows the same replacement schedule. Such effective tractor air filtration practices prevent debris from entering the engine, a common contributor to performance issues.

Maintaining these components not only promotes better John Deere engine health but also enhances overall tractor performance. Operators are advised to refer to their service manual and keep a log of all maintenance tasks performed, ensuring each part’s longevity and reliability.

| Component | Service Interval | Maintenance Task |

|---|---|---|

| Hydraulic/Transmission Oil Filter | After first 100 hours, then every 600 hours | Replace filter |

| Cab Recirculation and Fresh Air Filters | Every 300 hours | Clean filters |

| Engine Oil Filter (5225, 5325) | After 300 hours, then every 450 hours or annually with Plus-50 oil | Replace filter |

| Engine Oil Filter (5425 and up) | After first 100 hours, then every 450 hours or annually with Plus-50 oil | Replace filter |

| Fuel Filter | Every 300 hours | Replace filter |

| Primary Air Filter | Clean every 300 hours, replace every 1800 hours or yearly | Clean and replace filter as scheduled |

| Secondary Air Filter | Every 1800 hours or annually | Replace filter |

Conclusion

In sum, regular upkeep and immediate resolving of issues are fundamental for the John Deere 5525 troubleshooting process and contribute significantly to the tractor longevity. These proactive measures are not only a matter of routine; they are imperative for the sustained performance and dependability of your machinery. For every owner or operator, having a grasp on the varied functionalities of your tractor’s hydraulic and transmission systems equals enhanced proficiency in managing unforeseen setbacks.

An intimate understanding of service intervals such as oil changes, filter replacements, and overall cleanliness underpins what we define as effective maintenance. These procedures, when followed diligently, are your first line of defense against operational interruptions and can lead to a marked decrease in downtime. Such attention to detail ensures that each John Deere 5525 tractor continues to be a paragon of industry standards—a true workhorse in the agricultural scene.

Nevertheless, there are moments when an issue transcends the scope of even the most thorough maintenance routine. During these times, the expertise of a certified John Deere dealer or a seasoned technician becomes invaluable. Finalizing with this pivotal point: while robust self-sufficiency is admirable, recognizing when professional aid is needed can be the distinction between a quick fix and a costly overhaul. For any tractor, the goal remains clear—secure its operational vitality to reap the benefits of unyielding, efficient agricultural production.

FAQ

What are common hydraulic issues with the John Deere 5525 tractor?

Common hydraulic problems include the malfunctioning of the three-point hitch, issues with hydraulic fluid levels, contaminated fluid, clogged filters, and mechanical failure in lift piston components.

How do you troubleshoot John Deere 5525 hydraulic pump failures?

Begin by checking hydraulic fluid levels, filter condition, and fitting tightness to prevent pump cavitation. Test the loader’s operation or, if not available, assess the condition of the hydraulic pump directly.

What could cause the three-point hitch on my tractor not to stay up or go down?

This could be due to control valve problems, obstructions in the hydraulic valve system, low hydraulic fluid levels, or internal mechanical failures.

When should the hydraulic/transmission oil filter be replaced on a John Deere 5525?

The hydraulic/transmission oil filter should be replaced after the initial 100 hours of use, then every subsequent 600 hours to ensure optimal performance and prevent major issues.

What is the recommended maintenance schedule for the cab filters on a John Deere 5525?

The cab recirculation and fresh air filters should be cleaned after every 300 hours of tractor operation to maintain proper air quality and circulation within the tractor’s cabin.

How often should engine oil filters be changed in the John Deere 5525 series?

For models 5225 and 5325, the engine oil filter should be replaced after 300 hours and then every 450 hours or annually if using John Deere Plus-50 oil. Models 5425 and above require replacement after the initial 100 hours, then every 450 hours or annually with the recommended oil.

Why is it important to replace fuel filters regularly?

Replacing the fuel filter every 300 hours is vital to ensure the engine runs efficiently and to protect it from fuel impurities, thereby enhancing its longevity and performance.

How does one maintain the air filters in a John Deere 5525 tractor?

Primary air filters should be cleaned after every 300 hours and replaced every 1800 hours or yearly. Secondary air filters follow the same replacement schedule to ensure the engine receives clean air.

What are the benefits of regular maintenance and problem-solving for the John Deere 5525?

Consistent maintenance and prompt troubleshooting reduce downtime, extend the tractor’s life, ensure reliable and efficient operation, and prevent major mechanical failures.

How often should I check the diagnostic signals in my John Deere 5525?

Understanding and monitoring diagnostic signals, such as fuel levels, engine coolants, and hydraulic temperatures, is crucial for addressing potential problems proactively and ensuring the tractor operates within safe parameters.

What should I do if I encounter persistent or complex problems with my John Deere 5525?

For persistent or complicated issues, seek assistance from a John Deere dealer or a professional technician. They can provide a professional assessment and repair to avoid further damage to your tractor.

Leave a Reply