Are you experiencing issues with your John Deere 3520 tractor? Don’t worry, you’re not alone. Even a reliable machine like the 3520 can encounter common problems that can affect its performance. That’s why we’re here to help. In this article, we will delve into the most common issues faced by John Deere 3520 owners and provide you with expert troubleshooting tips and maintenance advice to keep your tractor running smoothly.

Whether you’re dealing with troublesome transmission, clutch problems, bagger issues, starting difficulties, steering troubles, or even engine stalling, we have you covered. We understand the frustration these problems can cause, but rest assured that with the right approach, they can be resolved.

Our comprehensive guide will walk you through each problem step-by-step, offering practical solutions to get your John Deere 3520 back in top condition. From checking transmission fluid levels and replacing worn seals to testing the PTO clutch and cleaning or replacing spark plugs, we will provide you with all the necessary steps to overcome these challenges.

Remember, regular maintenance is crucial to prevent potential problems and ensure the longevity of your John Deere 3520. By following our expert advice and implementing the recommended troubleshooting tips, you can avoid costly repairs and maximize the performance of your beloved tractor.

So, let’s dive right in and discover how you can conquer common John Deere 3520 problems with our valuable troubleshooting tips and maintenance advice.

Troublesome Transmission

The transmission of the John Deere 3520 can sometimes be problematic, especially if it has been used for extended periods without proper maintenance. Common transmission problems include loss of power, trouble shifting gears, and strange sounds when changing gears. To fix these issues, it is important to regularly inspect the transmission fluid levels, replace worn seals, and ensure proper lubrication. If there is a leak or air in the fluid, professional attention may be required.

Common John Deere 3520 Transmission Problems

1. Loss of Power: If you are experiencing a significant decrease in power while operating your John Deere 3520, it could indicate a transmission problem. This could be due to low transmission fluid levels, worn-out clutches, or a faulty torque converter. Regularly check the transmission fluid levels and consider replacing worn-out clutches or torque converters to resolve power loss issues.

2. Trouble Shifting Gears: Difficulty in shifting gears or gears slipping can be a sign of transmission problems. This could be caused by worn-out or damaged gears, worn clutch plates, or a malfunctioning shift linkage. Lubricating or replacing gears and inspecting the shift linkage can help resolve gear shifting problems.

3. Strange Sounds: Unusual noises, such as grinding, whining, or clunking, during gear changes are indicators of potential transmission problems. These noises may be caused by worn-out synchronizers, damaged bearings, or low transmission fluid. It is essential to inspect and replace worn-out components and ensure proper fluid levels to eliminate strange sounds.

Transmission Troubleshooting Tips

- Regularly check transmission fluid levels and top up if necessary.

- Inspect and replace worn-out seals to prevent fluid leaks.

- Ensure proper lubrication of transmission components.

- If there are signs of air in the transmission fluid, seek professional assistance.

Maintenance Advice for Transmission

- Follow manufacturer recommendations for fluid change intervals and use the recommended type of transmission fluid.

- Regularly inspect transmission components for signs of wear and tear.

- Replace worn-out clutches, gears, and synchronizers promptly.

- Have a professional technician perform a thorough transmission service to maintain optimal performance.

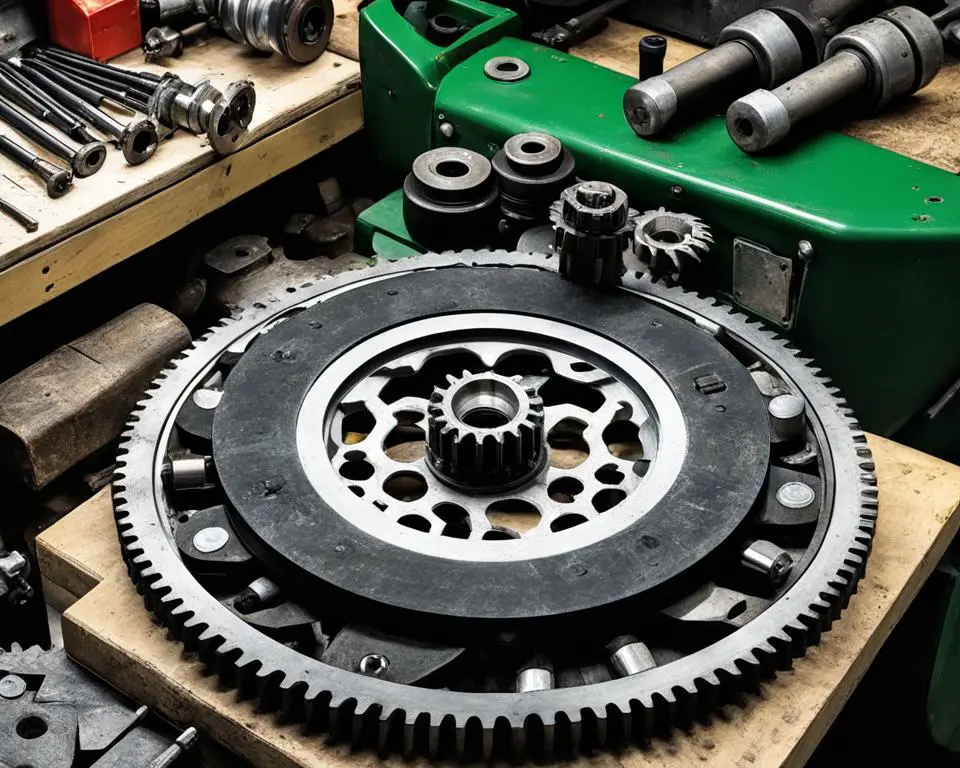

Clutch Problems

The John Deere 3520 may experience clutch problems, which can render the mower useless as power may not reach the blades. Signs of clutch problems include a stiff clutch, failure to engage or immediate disengagement of the PTO. These issues can be caused by damaged or slipping clutches, a faulty fuse, or a malfunctioning solenoid.

To fix clutch problems, you can start by testing the PTO clutch, checking the battery and fuse, and replacing damaged clutches while ensuring proper lubrication.

Here are some troubleshooting tips and maintenance advice for dealing with clutch problems on your John Deere 3520:

- Inspect the PTO clutch – Make sure the PTO clutch is not damaged or showing signs of slipping. If necessary, replace the clutch to ensure a proper connection.

- Check the battery and fuse – Ensure that the battery is fully charged and that the fuse is not blown. A faulty battery or fuse can cause issues with the clutch engagement.

- Replace damaged clutches – If you notice any damaged clutches, such as worn-out or broken components, replace them promptly. Damaged clutches can prevent the power from reaching the blades.

- Ensure proper lubrication – Apply lubrication to the clutch mechanism to reduce friction and ensure smooth operation. Regularly inspect the clutch for any signs of wear and tear.

- Seek professional assistance – If you’re unable to troubleshoot or fix the clutch problems on your own, it’s advisable to consult with a qualified technician who specializes in John Deere tractors. They can provide you with expert guidance and assistance in resolving the issue.

By following these troubleshooting tips and performing regular maintenance, you can address clutch problems effectively, ensuring that your John Deere 3520 operates smoothly and efficiently.

Issues With the Bagger

The bagger attachment for the John Deere 3520 can sometimes be troublesome, as it can fill up quickly and clog. This can be frustrating as you may need to constantly unclog it. Additionally, the bagger may occasionally fail to collect clippings. To address these problems, it is important to correctly install the bagger to prevent clogging, use high-lift or bagger blades instead of mulching blades for consistent lifting airflow.

Proper installation of the bagger is crucial in preventing clogs. Ensure that all connections are secure and that the bagger is aligned correctly with the tractor. Double-check the bagger chute to make sure it is clear of any debris or obstructions.

Another solution to prevent clogging is the use of high-lift or bagger blades instead of mulching blades. These blades are specifically designed to provide better lifting airflow, allowing the bagger to collect clippings efficiently without getting clogged.

Regular maintenance of the bagger is also important. Clean the bagger frequently to remove any accumulated debris or grass clippings. Inspect the bags for any signs of wear or damage and replace them if necessary. Check the bagger’s hoses and connections for any leaks or loose fittings.

By following these troubleshooting tips and maintenance advice, you can minimize bagger problems and ensure smooth operation of the bagger attachment for your John Deere 3520.

Here are some troubleshooting tips for John Deere 3520 bagger problems:

- Ensure correct installation of the bagger to prevent clogging.

- Use high-lift or bagger blades instead of mulching blades for better lifting airflow.

- Clean the bagger frequently to remove debris and grass clippings.

- Inspect bags, hoses, and connections for wear or damage.

- Replace worn or damaged parts as necessary.

| Problem | Solution |

|---|---|

| Quick clogging of the bagger | Properly install the bagger Use high-lift or bagger blades for better airflow |

| Bagger fails to collect clippings | Clean bagger frequently Inspect bags and connections for damage or wear Replace worn or damaged parts |

Starting Problems

Starting problems can be a common issue with the John Deere 3520 and can be caused by various factors. Possible culprits include a low or substandard fuel, a dirty or damaged carburetor, a clogged fuel line, worn-out spark plugs, or a faulty starter.

To fix starting issues, you can try the following troubleshooting tips:

- Park the tractor in a warmer place: If starting is difficult due to cold weather, try parking your John Deere 3520 in a warmer location to warm up the engine oil and improve starting performance.

- Jumpstart the battery: If the battery is dead, you can jumpstart it using jumper cables connected to another vehicle’s battery with the engine running. Make sure to follow proper safety precautions while jumpstarting.

- Refill the gas tank: If the gas tank is empty, refill it with the recommended fuel for your John Deere 3520. Using low-quality fuel or the wrong fuel type can cause starting problems.

- Replace the starter assembly: If the starter is faulty, it may need to be replaced. Consult the John Deere 3520 manual or a professional technician for guidance on replacing the starter assembly.

- Clean or replace carburetors and spark plugs: A dirty or damaged carburetor or worn-out spark plugs can affect starting. Clean or replace the carburetors and spark plugs as needed.

By following these troubleshooting tips, you can address the starting problems with your John Deere 3520 and ensure smooth and reliable operation.

Steering Problems

The John Deere 3520 may encounter steering problems that can impact its overall performance and your driving experience. Some common issues you might experience include a stiff or unresponsive steering wheel, shakiness, or unusual noises while driving.

These steering problems can be attributed to various factors, such as a loose drag linkage, imbalanced tires, or a faulty steering support assembly. When the drag linkage becomes loose, it can affect the control and responsiveness of the steering. Imbalanced tires can cause unstable movements, resulting in shakiness while driving. A faulty steering support assembly can also contribute to the overall steering deficiencies.

To address these steering problems, it is important to conduct a thorough inspection of the steering wheel assembly and suspension system. Check for any signs of wear, damage, or misalignment. Tighten or replace any loose or worn components, such as slipped gears or dislodged ball joints. In some cases, you may need to replace bearings and bushes if they are worn out or damaged.

In addition, ensure that your tires are properly balanced and inflated. Imbalanced tires can significantly affect the smoothness of your steering and overall driving experience. Regularly check the tire pressure and make adjustments as needed.

By addressing these steering problems promptly, you can restore the optimal functionality of your John Deere 3520 and enjoy a smoother and more controlled driving experience.

Remember to always refer to the manufacturer’s guidelines and consult a professional if you encounter any difficulties during the troubleshooting process.

Engine Stalling

While the John Deere 3520 is a reliable tractor, there are instances where engine stalling can occur, although it is relatively rare. Engine stalling typically arises due to issues with fuel quality, spark plugs, or the carburetor. Inadequate, low-quality, or contaminated fuel can disrupt the engine’s performance and lead to stalling. Damaged spark plugs can cause misfires, resulting in engine shutdown. Additionally, a failing carburetor may struggle to deliver a consistent fuel-air mixture, adversely affecting the engine’s operation.

To prevent engine stalling in your John Deere 3520, follow these troubleshooting tips and maintenance advice:

- Use high-quality fuel from reputable sources to ensure proper engine performance.

- If you suspect contaminated fuel, flush the fuel line to remove any impurities.

- Regularly inspect and replace damaged or worn spark plugs to maintain optimal ignition.

- Address carburetor issues promptly by cleaning or replacing it, as necessary, to prevent power loss and stalling.

By implementing these maintenance practices, you can minimize the risk of engine stalling in your John Deere 3520 and enjoy uninterrupted performance during your tasks.

Conclusion

Despite the common problems that can occur with the John Deere 3520, it is still a reliable and durable tractor with impressive features. Regular maintenance and proper troubleshooting can address most of these issues and ensure optimal performance.

By following the troubleshooting tips and maintenance advice provided in this article, you can overcome common problems and enjoy the full potential of your John Deere 3520. Remember to always refer to the manufacturer’s instructions and consult a professional if needed.

Ensuring the maintenance of your John Deere 3520 is of utmost importance. Regular inspections and timely repairs can prevent issues before they become major problems, extending the lifespan of your tractor and saving you money in the long run.

Investing time in proper maintenance and troubleshooting not only eliminates the frustration of dealing with frequent breakdowns, but it also enhances the overall performance and efficiency of your John Deere 3520. So, take care of your tractor, and it will take care of you for years to come.

FAQ

What are some common problems with the John Deere 3520?

Common problems with the John Deere 3520 include PTO clutch issues, starting problems, steering difficulties, transmission issues, and engine stalling.

How can I troubleshoot transmission problems in my John Deere 3520?

To troubleshoot transmission problems, regularly inspect the transmission fluid levels, replace worn seals, and ensure proper lubrication. If there is a leak or air in the fluid, professional attention may be required.

What should I do if I’m experiencing clutch problems with my John Deere 3520?

If you’re experiencing clutch problems, start by testing the PTO clutch, checking the battery and fuse, and replacing damaged clutches while ensuring proper lubrication.

How can I address issues with the bagger attachment on my John Deere 3520?

To address problems with the bagger attachment, correctly install the bagger to prevent clogging and use high-lift or bagger blades instead of mulching blades for consistent lifting airflow.

What should I do if I’m having trouble starting my John Deere 3520?

If you’re having trouble starting your John Deere 3520, you can park the tractor in a warmer place if starting is difficult due to cold weather, jumpstart the battery if it is dead, refill an empty gas tank with the recommended fuel, replace the starter assembly if necessary, and clean or replace dirty or damaged carburetors and spark plugs.

How can I address steering problems with my John Deere 3520?

To address steering problems, inspect the steering wheel assembly and suspension system, ensure balanced and inflated tires, and fix slipped gears, dislodged ball joints, or replace bearings and bushes if necessary.

What can I do to prevent engine stalling in my John Deere 3520?

To prevent engine stalling, use high-quality fuel, flush the fuel line if contaminated, replace spark plugs when needed, and address carburetor issues to avoid power loss.

How can I ensure optimal performance for my John Deere 3520?

To ensure optimal performance, regularly maintain your John Deere 3520 by following the troubleshooting tips and maintenance advice provided. Always refer to the manufacturer’s instructions and consult a professional if needed.

Leave a Reply