For many John Deere tractor owners, the 3 point hitch is an essential component for a variety of tasks. However, when faced with John Deere hitch issues, it can become a significant inconvenience and hinder your agricultural or landscaping projects. It’s not uncommon for these robust machines to encounter challenges that require tractor hitch troubleshooting. Many factors can contribute to hydraulic hitch repair needs, ranging from simple wear and tear to more complex hydraulic system failures.

Identifying the root of the problem is the first step in addressing any malfunctions. Whether your hitch fails to lift, drops unexpectedly, or encounters slow movement, understanding the hydraulic system and potential mechanical concerns is crucial. Proper diagnosis and timely resolution play pivotal roles in ensuring your John Deere tractor operates efficiently, saving you time and resources in the long run.

Key Takeaways

- Recognizing and diagnosing John Deere hitch issues are essential for timely repairs.

- Regular maintenance can prevent many common tractor hitch troubleshooting scenarios.

- Understanding the hydraulic system is fundamental for successful hydraulic hitch repair.

- Identifying symptoms accurately can lead to faster and more effective problem resolution.

- A systematic approach reduces downtime, ensuring tractor performance and reliability.

Introduction to John Deere’s Hydraulic 3 Point Hitch System

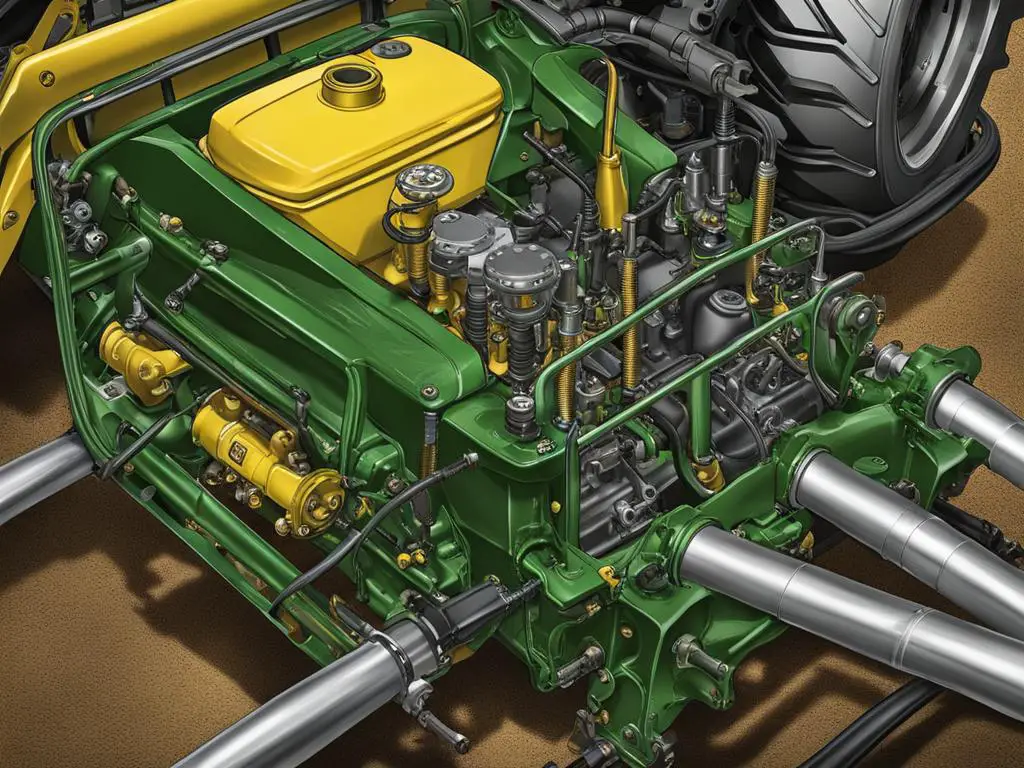

The backbone of versatile work on the farm, a John Deere tractor’s hitch system, is a critical component for myriad tasks. The 3-point hitch hydraulic system particularly stands out for its adaptability and design sophistication—qualities essential for efficient, uninterrupted agricultural operations. The myriad John Deere tractor components work in harmony to ensure that implements are hitched securely and lifted with precision, requiring thorough knowledge of the system for effective utilization and maintenance. This introduction lays the foundation for how this complex system operates and is maintained.

Essential Understanding of Hydraulic Lift Operation

At the heart of the hitch’s functionality is the hydraulic lift system. Utilizing the principles of fluid dynamics, the hydraulic lift enables smooth elevation changes of connected implements, which is crucial for a variety of field operations. This not only preserves the life of both the tractor and the attachment but also optimizes performance aligned to user needs.

Key Components and Their Functions

The primary components of the John Deere 3-point hitch system include the hydraulic pump, lift control lever, and hydraulic control valve. Each plays a pivotal role in implement operation:

- Hydraulic Pump: Generates the necessary oil pressure to elevate the implements.

- Lift Control Lever: Facilitates the operator’s command over the hitch position, essentially acting as a bridge between user action and mechanical response.

- Hydraulic Control Valve: Manages the flow of hydraulic fluid, ensuring that lifts are smooth and controlled.

Maintenance Influence on Hitch Performance

Maintenance is not merely a complimentary activity but is central to the operational longevity of the 3-point hitch system. Factors such as a full hydraulic fluid reservoir, appropriate oil viscosity, clean filters, and secure hydraulic connections are vital. These components work interdependently, meaning that the failure of one could lead to a cascade of issues across the system if not addressed promptly. Regular 3 point hitch maintenance procedures help avert potential breakdowns and maintain optimal performance.

| Component | Function | Maintenance Key Points |

|---|---|---|

| Hydraulic Pump | Pressure generation | Check for leaks; ensure cleanliness |

| Lift Control Lever | Position adjustment | Regular lubrication |

| Hydraulic Control Valve | Fluid flow management | Inspect for blockages; check seals |

Maintaining the intricate balance of the 3-point hitch hydraulic system on your John Deere tractor is foundational for agronomic success. Draw upon the guidance provided here to ensure your equipment’s functionality remains optimal. With each component playing a critical role, understanding their operation and maintenance not only aids in problem-solving but also prevents issues before they manifest.

Identifying Common Symptoms of John Deere 3 Point Hitch Issues

Recognizing the signs of 3 point hitch problems is critical in maintaining the functionality and performance of your John Deere tractor. Various symptoms can indicate malfunctions, such as the hitch drifting down, failure to rise, or staying in the up position without descending. Such irregularities often point to a compromised system, where a tractor hitch malfunction might be caused by issues like low fluid levels, dirty hydraulic fluid, or a clogged hydraulic filter.

Understanding these hydraulic hitch symptoms is the first step towards efficient troubleshooting and repair. Let’s explore and delineate common indicators of hitch dysfunction:

| Symptom | Possible Cause | Notes |

|---|---|---|

| Hitch drifting down | Hydraulic fluid leak or bad seals | Check for visible leaks and worn seals |

| Hitch failure to rise | Low hydraulic fluid levels | Ensure fluid is topped off and has no contaminants |

| Hitch stuck in up position | Control valve malfunction | Inspect for blockages or mechanical linkage issues |

| Slow hitch descent | Clogged hydraulic filter | Clean or replace the filter to restore flow |

These hydraulic hitch symptoms can help tractor owners and technicians determine whether the problem is hydraulic, mechanical, or related to control linkages, guiding them to the most relevant area for further diagnosis and repair.

Addressing these issues promptly ensures your tractor is performing at its peak and can prevent a simple repair from becoming a complex, costly problem.

Step-by-Step Diagnostic Guide for John Deere 3 Point Hitch Problems

When it comes to tractor hitch diagnostics, possessing a comprehensive step-by-step repair guide is indispensable for the modern farmer or tractor owner. Tractors, especially those from John Deere, are engineered for resilience and precision. Nonetheless, like any complex machinery, they can encounter issues, particularly with the 3 point hitch system. Our guide here is tailored to assist with efficient John Deere troubleshooting, helping to identify and resolve hitch problems methodically.

The following diagnostic steps provide a structured approach for ascertaining the cause of hitch issues you may encounter:

- Verify the Hydraulic System’s Health: Begin with assessing the hydraulic system. Check other hydraulic-powered functions, particularly the front loader, to ensure they are operating efficiently. This will help you determine whether the issue is with the pump or other components.

- Examine the 3 Point Control Handle: Inspect the control handle for any missing parts or apparent damage. A missing rod or retaining pin can lead to a malfunctioning hitch, and may be a relatively straightforward fix.

- Assess the Hitch’s Persistency: If the hitch falls or leaks down, investigate the selective control valve and lift arms. It might be a case of worn or bad seals that need replacement.

- Test for Descent: Should the hitch refuse to go down, the issue might be the flow control valve. It’s essential to check for blockages or malfunctions in this part.

- Consider Internal Mechanical Issues: If none of the external checks rectify the problem, you may be dealing with a deeper mechanical issue. This could possibly necessitate disassembling parts of the hitch mechanism and inspecting for more intricate problems like internal seal leaks or failures.

It should be noted that although these steps are significant in identifying common hitch problems, the actual repair process may require specific tools and technical expertise. Consulting with a professional or referring to your John Deere operator’s manual could provide further assistance for delicate procedures.

By following this guide, you’ll be equipped to handle various John Deere 3 point hitch complications, ensuring your tractor remains an effective workhorse on your farm.

Isolating the Specific Failure in the Hitch Mechanism

The dependability of a John Deere tractor is often as strong as its weakest link, and when that link involves a hitch mechanism failure, it becomes imperative to isolate and rectify the fault with immediate and accurate precision. Targeting the exact issue requires a sequential approach to hydraulic system analysis, inspecting crucial high-pressure components, and careful control valve inspection.

Analyzing Hydraulic System Failures

Successful hydraulic system analysis is a meticulous process. It begins with testing the integrity of pressure lines, ensuring they are void of any leaks or damages that could compromise the overall hydraulic power. Confirmation of proper filter conditions follows suit; a clean and unobstructed filter is necessary for maintaining a consistent hydraulic flow. Equally critical is verifying that hydraulic fluid levels are not only sufficient but also free of contamination, as the right fluid quality is essential for the operation of the hitch mechanism.

High-Pressure Components Inspection

Inspecting key high-pressure components can unearth issues contributing to hitch mechanism failure. Attention to the hydraulic pump and the lift cylinder is vital – any compromise in their seals could mean a consequential loss in the system’s ability to lift and hold heavy implements. A thorough examination for leakages is a non-negotiable step in ensuring the health and functionality of the system’s high-pressure elements.

Mechanical Linkage and Control Valve Checks

Mechanical linkages play a critical role by physically connecting the control valve to the hitch mechanism. Malalignment or wear within these linkages can result in operational failure or erratic behavior of the hitch. A comprehensive control valve inspection also becomes essential; any debris or blockages could severely impact the modulation of hydraulic fluid flow and pressure. If hitch movement is found to be abnormal, disassembling the speed control valve to investigate for internal blockage could prove to be a successful troubleshooting intervention. With every step in this diagnostic journey, the objective remains clear: restore and maintain the hitch mechanism’s reliability and performance.

Should you be confronted with a diagnosis that extends beyond the scope of these suggestions, consulting with a professional service technician who specializes in John Deere tractor repairs is highly recommended. Proper maintenance and timely troubleshooting are your best defense against prolonged downtime and costly repairs, ensuring your tractor remains a pivotal asset to your operations.

Solving John Deere 3 Point Hitch Problems

Tractor maintenance is pivotal for the longevity and efficient performance of agricultural machinery. In the realm of John Deere tractors, the hitch system demands particular attention. This section delves into concrete solutions for 3 point hitch difficulties, focusing on hydraulic fluid maintenance, tractor parts replacement, and hitch functional adjustment. By addressing these critical areas, operators can restore and maintain their tractor’s capabilities.

Addressing Hydraulic Fluid and Filtration Issues

Hydraulic fluid maintenance forms the foundation of a functioning tractor hitch system. Ensuring the use of the correct type of clean oil is essential for reducing wear and preventing hydraulic component failures. A clogged hydraulic filter can impede fluid flow, leading to inadequate hitch performance. Regular assessment and replacement of hydraulic filters are part of proactive tractor upkeep that can forestall more severe issues.

Replacing Defective Parts and Seals

Wear and tear are inherent in tractor operation, necessitating tractor parts replacement periodically. The hitch mechanism’s successful function relies on the integrity of every part, from the lift piston to the smallest seal. Detecting and substituting defective or worn components can avoid the hitch’s gradual deterioration, ensuring responsive and reliable lift operations.

Adjustments for Optimal Functionality

Hitch functional adjustment is another critical aspect of hitch troubleshooting. Beyond just part and fluid maintenance, the precise setting of controls, such as the speed control valve, is necessary for achieving the hitch’s appropriate drop rates and lift capacities. These meticulous adjustments ensure the system’s optimal performance and suit the demands of various agricultural tasks.

| Issue | Maintenance Action | Outcome |

|---|---|---|

| Inadequate hydraulic fluid | Top-up fluid, ensure correct type and cleanliness | Restored fluid pressure for full hitch operation |

| Hydraulic fluid contamination | Clean or replace filters, flush system if necessary | Enhanced fluid quality, avoiding valve or pump damage |

| Worn out seals or defective parts | Identify and replace damaged components | Prevention of leaks and loss of hydraulic power |

| Improper hitch adjustment | Inspect and modify control valve settings | Accurate hitch operation according to workload |

By following a stringent diagnostic process that encompasses the hydraulic system, high-pressure components, mechanical linkages, and control valves, farmers and tractor owners can efficiently tackle common hitch-related challenges. Such diligent practices go a long way in bolstering a John Deere tractor’s functionality, making it an indispensable asset in various agricultural endeavors.

Conclusion: Enhancing Tractor Performance Through Effective Hitch Troubleshooting

The pursuit of efficient farm operations often hinges on the performance of essential machinery like the John Deere tractor. In this regard, an effective hitch troubleshooting process stands as a testament to a farmer’s diligence and technical acumen. Wrapping up the diagnostic journey, we’ve seen how a robust understanding of the interplay between hydraulic systems, mechanical components, and operator controls is paramount in addressing the multifaceted nature of 3 point hitch issues.

Results from this careful troubleshooting and the resulting John Deere tractor repair conclusion affirm the importance of proactive maintenance and timely intervention when anomalies arise. Addressing each identified symptom with a calculated response not only alleviates current concerns but also forestalls potential future disruptions. By adhering to a systematic approach, tractor owners can safeguard against performance hitches and extend the lifecycle of their cherished workhorse.

The harmony between preventative care and reactive repairs defines the excellence of tractor performance. Therefore, well-executed maintenance routines coalesced with prompt and precise hitch troubleshooting form the backbone of agricultural success. Indeed, an informed resolve to these technical challenges ensures the dependable operation of John Deere tractors, allowing them to fulfill their role in facilitating a thriving, productive farmstead.

FAQ

What are the common symptoms of a malfunctioning John Deere 3 point hitch?

Common symptoms of issues with the hitch include the hitch drifting down, problems with rising, staying in the up position, slow descent, or a complete failure to lift. These symptoms can point to hydraulic system problems or mechanical linkage failures.

What are the initial steps for troubleshooting John Deere hitch issues?

Begin by verifying the tractor’s hydraulic system health, including the operation of other hydraulic functions like the loader. Check the hydraulic fluid levels, filter condition, and inspect the 3 point control handle for any disconnection or parts failure.

How do I diagnose hydraulic system failures in the 3 point hitch of a John Deere tractor?

Diagnosing hydraulic system failures involves checking the hydraulic fluid for proper levels and cleanliness, inspecting the hydraulic filter for clogs, testing pressure lines, and ensuring the hydraulic pump and lift cylinder are free from leaks and have intact seals.

What should I inspect if my tractor’s hitch won’t stay up or leaks down?

If the hitch won’t maintain its position or leaks down, inspect the selective control valve, lift arms, and check for bad seals or other wear that may cause fluid to bypass within the system.

How can I address slow descent issues with my John Deere 3 point hitch?

Problems with slow descent may be related to the speed control valve. Inspect for internal blockages or necessary adjustments to ensure the valve regulates the descent rate effectively.

What are some potential causes if my John Deere tractor’s hitch won’t lift at all?

A hitch that won’t lift could be due to low hydraulic fluid levels, air in the hydraulic system causing cavitation, clogged filters, or internal mechanical failures such as a damaged lift piston or problems with the lift control lever and hydraulic control valve.

When should I consider replacing parts or seals on my tractor’s hitch?

Part replacement and seal repair should be considered when you’ve detected leaks, degraded seals, or damaged components such as the lift piston, lift cylinder, or control valves during the diagnostic process.

How can I ensure optimal functionality of my John Deere 3 point hitch after troubleshooting?

After addressing any identified issues with hydraulic fluid, filtration, replacing defective parts, and seals, make precise adjustments to components like the speed control valve for drop rates and verify the proper alignment and operation of mechanical linkages for optimal functionality.

What’s the significance of routine maintenance on my John Deere 3 point hitch performance?

Regular maintenance, including ensuring proper hydraulic fluid levels, cleaning filters, checking for secure fittings, and maintaining control valves, is crucial for minimizing performance issues and prolonging the life and reliability of your tractor’s hitch mechanism.

Where can I find specific troubleshooting information for my John Deere 3 point hitch model?

For model-specific troubleshooting information, consult the operator’s manual for your tractor, visit the John Deere website for support resources, or contact a John Deere dealer or certified technician for expert guidance.

Leave a Reply