Understanding the complexities of maintaining a robust farm vehicle like the John Deere 7420 is essential for ensuring peak tractor performance and longevity. Despite its capabilities and reliability, operators may sometimes face unexpected engine issues, prompting a need for adept John Deere 7420 troubleshooting. These challenges can range from the engine running roughly after brief periods of activity to confronting overheating solutions when tasked with intense agricultural operations.

Moreover, other essential functions such as the hydraulic system can manifest hydraulic problems, affecting the tractor’s functionality. Familiarizing oneself with the typical faults this machinery can exhibit empowers users to identify and address the root causes effectively, averting prolonged downtime and ensuring that their John Deere 7420 operates at its best.

Key Takeaways

- Identifying engine misfires and rough operation for early intervention can save significant time and effort.

- Understanding potential causes and solutions for the John Deere 7420’s overheating can prevent long-term damage.

- Awareness of hydraulic issues can lead to more precise diagnostics and swift, effective repairs.

- Implementing a systematic approach to troubleshooting safeguards the complex systems integral to the tractor’s performance.

- Maintaining regular inspections and addressing minor concerns promptly can enhance the longevity of the John Deere 7420.

Understanding John Deere 7420 Fuel System Quirks

John Deere 7420 tractor owners frequently encounter a perplexing issue where the engine experiences engine misfire and runs roughly, only to rectify itself after a restart. Navigating these problems requires a methodical approach to fuel system troubleshooting, with attention paid to anomalies like air in fuel lines and potential electronic or computer-related issues.

Possible Causes for Engine Running Rough

Although many components within the tractor’s fuel system, like fuel lines, fuel filters, and the fuel pump, have been replaced or adjusted, farmers still report a transient roughness in engine performance. This condition suggests that there are underlying issues yet to be identified, necessitating a broadened analysis towards the fuel system maintenance practices and parts integration for diagnosis.

Troubleshooting Tips: Air in Fuel System

It’s surmised that an air leak may have snuck into the fuel system, causing the engine to run improperly. A technique for isolating this condition is to bleed the injector lines while the engine runs, which has proven to alleviate similar issues in other farm machinery such as Kubota tractors.

| Issue | Symptom | Possible Cause | Troubleshooting Action |

|---|---|---|---|

| Engine Misfire | Engine runs rough, misses on one or more cylinders | Air in fuel lines | Bleed air from injector lines |

| Failure to Start | Engine does not turn over, or shuts down soon after starting | Clogged fuel filters or faulty fuel pump | Replace fuel filters and fuel pump |

| Inconsistent Engine Performance | Engine performance improves only after restarting | Potential electronic/computer issues or unknown air leaks | Electrical diagnostics and air leak inspection |

Electrical and Computer Causes Review

Understanding that the immediate improvements post-restart are unlikely to stem from mechanical changes within the fuel system, the scope expands to include electric components and computer functions. No error codes complicate the process; however, confirming the actual version of the fuel system in use (whether a Mexican version with a Lucas or Stanadyne pump or a worldwide version with an electronically controlled system) can have substantial implications on the troubleshooting approach.

John Deere 7420 Overheating Issues and Solutions

Owners of the resilient John Deere 7420 tractor often face a perplexing overheating issue, particularly during heavy-duty operations such as grain vacuuming or extensive mowing. The high hydraulic temperature triggers onboard diagnostics to flag error messages and, in some cases, shuts down the tractor to prevent damage. In addressing these overheating challenges, it is essential to scrutinize a range of potential contributing factors.

Hydraulic System Checks and Fixes

Hydraulic system maintenance is pivotal when confronting overheating issues. Regular evaluations and timely interventions can prevent the hydraulic temperature from climbing too high. Implementing a comprehensive cooling system check coupled with this maintenance can ensure the hydraulic fluid remains at a temperature within the safe operating range.

Addressing Cooling System Complications

Initial investigations into overheating may lead to actions like cleaning the radiator or replacing hydraulic fluids and filters; however, persistent problems demand a closer look. Possible culprits requiring attention include airlocks within the cooling system or a malfunctioning low-temperature thermostat—an essential component for regulating the hydraulic system’s heat exchange process.

The Role of Hydraulic Oil Level and Quality

To ensure optimal oil levels, operators must regularly check and maintain proper oil levels as per the manufacturer’s guidelines. Not only do correct oil levels play a crucial role in overheating resolution, but the quality of the hydraulic oil itself can dramatically impact the system’s efficiency and temperature control. Diligence in these areas can help mitigate overheating, ensuring a consistent, optimal tractor performance.

| Issue | Solution | Regular Maintenance Task | Notes |

|---|---|---|---|

| Hydraulic Overheating | Check and fill hydraulic fluids; inspect radiator | Cooling system fluid level check | Use manufacturer-recommended fluids |

| High Operating Temperature | Investigate thermostat functionality | Cooling system diagnostic | Consider ambient temperature and workload |

| Oil Level Fluctuations | Replenish oil levels appropriately | Regular monitoring of sight glass | Wait for hydraulic system to settle before measuring |

Each of these facets—from meticulous hydraulic checks to cooling system optimization, and vigilant monitoring of hydraulic oil levels—is a cornerstone in the broader scope of ensuring the enduring reliability of the John Deere 7420. By thoroughly addressing these overheating issues and solutions, owners and operators can achieve a productive and uninterrupted workflow, even under taxing conditions.

Preventing Transmission Troubles in the John Deere 7420

Owners of the John Deere 7420 tractor recognize the Integral Power Shift Transmission (IVT) for its seamless operation that dramatically enhances the farming experience. However, the sophisticated nature of this transmission system also means that it requires diligent IVT transmission maintenance to ensure it continues to operate without hiccups. Staying ahead of potential issues not only curtails downtime but also preserves the intricate mechanics of the transmission, contributing to a long service life and sustained hydraulic system performance.

Maintaining the IVT for Optimal Performance

To prevent the common issues that could diminish the performance of your John Deere 7420’s IVT, regular maintenance checks are paramount. This involves routine inspections for leaks, verifying the correct hydraulic fluid levels, and ensuring the IVT selector is set appropriately for the intended task. A neglected IVT can lead to unexpected tractor shutdowns and overheating alerts—both of which can abruptly interrupt critical agricultural tasks. Here are key prevention strategies:

- After the tractor has been idle, allow time for hydraulic fluid to settle before checking the oil levels.

- Regularly clean the cooling system and replace filters to prevent overheating.

- Be vigilant for signs of wear and tear or damage to the transmission components, addressing them promptly.

- Consult your John Deere manual for specific IVT transmission maintenance schedules and follow them meticulously.

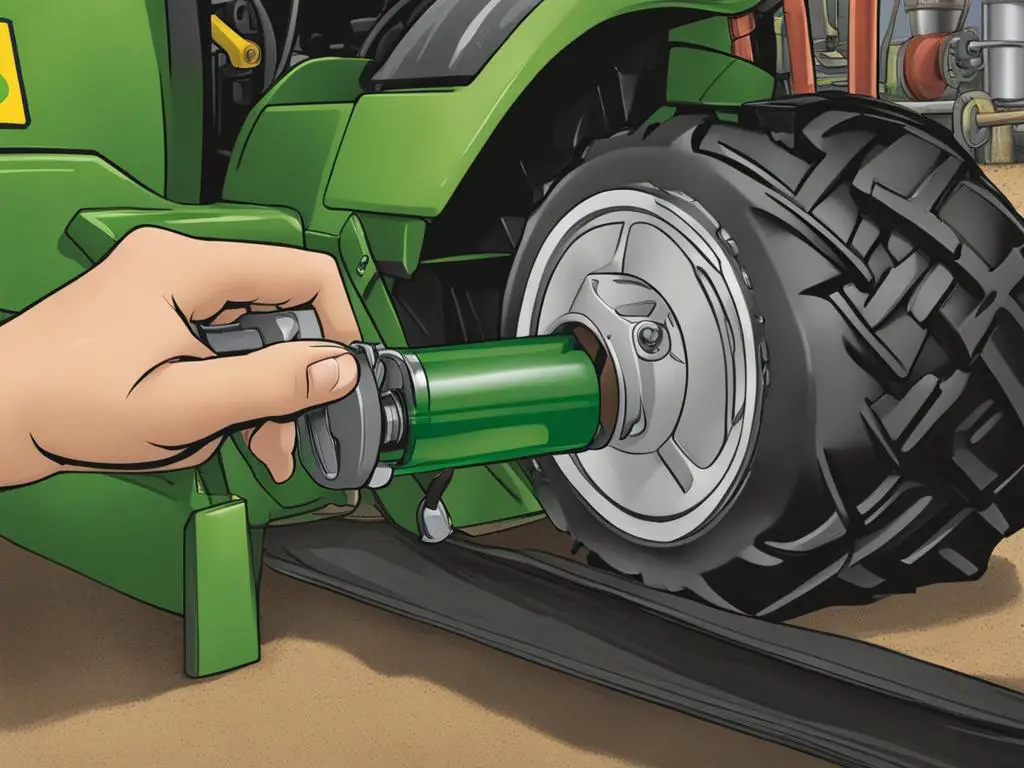

Identifying Common Hydraulic and PTO Concerns

Aside from transmission care, ensuring the PTO operation runs smoothly is essential, as is maintaining the entire hydraulic system. Issues such as fluctuating hydraulic fluid levels can occur during high-demand operations, and if not rectified, could lead to severe damage or operational failures. Here are some areas where attention to detail can avert common hydraulic and PTO problems:

- Observing the quality and consistency of the hydraulic fluid can reveal potential issues with the hydraulic system before they worsen.

- Listening for bypassing noises or leaks in the hydraulic system, particularly around the power beyond valve, can indicate internal damage that needs inspection.

- Adjusting the PTO operation to match the task at hand can prevent undue stress on the tractor’s hydraulics.

- Familiarize yourself with signs that may suggest an overheating hydraulic system, such as error messages on the dash, and respond promptly to them.

In conclusion, rigorous attention to the IVT transmission maintenance, proper PTO operation, and overall hydraulic system performance is indispensable for minimizing the risk of transmission troubles. By regularly utilizing these tips and carrying out the actionable steps, John Deere 7420 owners can secure the tractor’s capabilities and prevent the frustrations of unforeseen operational disturbances.

John Deere 7420 Problems with Three-Point Hitch

When it comes to optimizing the functionality of farm equipment, addressing a three-point hitch malfunction in the John Deere 7420 is paramount. Users have reported instances where the hitch fails to respond appropriately, leading to a hitch operation error that can significantly impede agricultural productivity. A common manifestation of this issue is the display of a ‘stepper error’ on the tractor’s dashboard, indicating a possible stepper motor failure.

The stepper motor is integral to the hitch’s operation; thus, encountering error codes such as 303041 and 303044 upon subsequent engine diagnostics necessitates immediate attention. Such trouble codes often hint at problems with the stepper motor coils or the electrical connections vital for seamless machinery operation.

- Manual Stepper Motor Adjustment:

- Locate the round cap on top of the stepper motor and remove it to access the manual adjustment screw.

- Gently turn the screw left and right to manually operate the hitch and discern whether hydraulic or linkage issues are present.

- Diagnostic Steps for Stepper Motor Issues:

- Clear error codes from the system and monitor to see if they reappear, which would strongly suggest stepper motor-related problems.

- Conduct thorough inspections of all associated wiring and connections to rule out electrical issues.

- Replacement and Repair Solutions:

- If diagnostics confirm stepper motor failure, the motor will require replacement to restore the three-point hitch function.

- Electrical diagnostics might also lead to the discovery of wiring issues that necessitate repair or replacement.

| Error Code | Indicated Issue | Troubleshooting Action | Outcome |

|---|---|---|---|

| 303041 | Stepper Motor Coil 1, Open Lead | Inspect and test coil wiring | Replace coil or wiring if necessary |

| 303044 | Stepper Motor Coil 2, Circuit Fault | Conduct electrical diagnostics | Repair electrical connections or replace stepper motor |

It is crucial for operators to understand that resolving these issues not only reinstates the hitch’s functionality but also ensures the John Deere 7420 operates with utmost efficiency. While addressing a three-point hitch malfunction might seem formidable, following these structured troubleshooting steps can simplify the process and lead to quick recovery of hitch operations.

Diagnosing and Correcting Electrical and Sensor Failures

Farmers with John Deere 7420 tractors are often well-acquainted with the complexities of electrical troubleshooting. Whether it’s interpreting dashboard error messages or engaging in sensor fault diagnosis, the task demands a meticulous eye for detail. Sensor fault diagnosis is particularly critical, as these components are key to the proper function of the tractor’s various systems, and misdiagnoses can lead to unnecessary replacements or overlooking the real issue at hand.

One common scenario involves the Power Take-Off (PTO) system; an operator might find that, despite indication lights suggesting active status, the PTO itself remains dormant. This anomaly often points to an electrical fault, where a deeper diagnostic of the electrical system, particularly the sensors and connections associated with the PTO, might reveal the root cause. Conversely, persistent overheating messages might mislead operators to focus on the cooling system when, in fact, a sensor failure is triggering false alerts.

| Error Displayed | Potential Electrical/Sensor Issue | Diagnostic Action |

|---|---|---|

| PTO Inactive | PTO Sensor Malfunction or Circuitry Problem | Test PTO Sensor and Electrical Connections |

| Overheating Alert | Faulty Temperature Sensor | Check and Replace Temperature Sensors |

| Stepper Error on Hitch | Stepper Motor Electrical Failure | Assess Stepper Motor and Wiring Integrity |

For those facing dashboard error messages, the recommended first step is often to clear the codes and monitor if they reappear. This step, while seemingly basic, is crucial for confirming whether a given issue was a simple glitch or a symptom of a larger underlying problem. Should the errors recur, each sensor and stepper motor linked to the code needs to be carefully examined, possibly including the replacement of the faulty parts to return the tractor to its fully operational state.

- Verify the integrity of all wiring connections, especially in areas prone to wear or rodent damage.

- Use manufacturer-specific diagnostic tools to accurately read error codes and sensor data.

- Engage in routine inspections to catch early signs of electrical degradation before systems fail.

In essence, adept electrical troubleshooting not only solves immediate functional hiccups but also fortifies the tractor against potential future complications. With a proactive stance on sensor fault diagnosis, farmers can ensure their John Deere operates reliably when it matters most.

Conclusion

In the realm of agricultural machinery, effective tractor troubleshooting is instrumental in maintaining overall performance and reliability. The John Deere 7420, a workhorse of modern farming, is no exception. Owners have been guided through common issues and solutions that contribute to the machine’s intricate operations. The journey through this article has illustrated that a deep understanding of each subsystem is critical for enhancing John Deere 7420 longevity.

Review of Key Takeaways for John Deere 7420 Owners

Vigilance in maintaining the fuel system, correctly diagnosing sensor errors, and responding to transmission alerts underpin the tractor’s operational excellence. Regularly scheduled preventive maintenance checks are critical in avoiding disruptions in daily farming activities. Identifying problems with the hydraulic system, such as air in the lines or electrical issues with the PTO, proves just as crucial. These key takeaways underscore the importance of proactive, informed maintenance strategies for John Deere 7420 owners.

Final Thoughts on Maintaining Tractor Performance

Preventive maintenance is the linchpin of enduring tractor performance, ensuring that common problems are addressed swiftly and accurately. This care extends the service life of the John Deere 7420, securing its role as a valuable asset in the agricultural industry. By embracing a preventive approach to tractor care, operators can ensure their equipment functions smoothly, minimizing the likelihood of unforeseen mechanical or electronic issues. Thus, the astute farmer remains at the ready, equipping themselves with knowledge and understanding, to sustain the peak health of their John Deere 7420.

FAQ

What are the common engine issues that John Deere 7420 owners might experience?

Owners may encounter engine running rough shortly after start-up, which may be due to air in the fuel lines, electrical or computer issues. The engine might require a restart for normal function, and troubleshooting is complicated by the absence of error codes.

How can I troubleshoot fuel system issues in my John Deere 7420 tractor?

Start with ensuring there are no air leaks in the fuel system. Check all fuel lines, fuel filters, and the fuel pump. If a rough-running engine persists, consider potential electrical or computer-related causes that could be affecting the fuel system, depending on your tractor’s specific pump model (Lucas, Stanadyne, or electronic control).

What should I check if my tractor is overheating, especially when using implements like a grain vac or rotary cutter?

Investigate the hydraulic system by checking for airlocks in the cooling system or a malfunctioning thermostat. Ensure the hydraulic fluid and filters are clean and oil levels are correct. Inspect the electric water pump and power beyond valve for any signs of failure that could contribute to the overheating problem.

How do I maintain the IVT for optimal performance in my John Deere 7420?

Regular maintenance should include verifying the hydraulic oil levels after the machine settles, paying attention to the IVT selector’s position, checking the low-temperature cooling circuit, and ensuring there are no leaks or bypassing noises from the power beyond valve. Sensor faults should also be considered if there are issues with consistent power delivery or overheating.

What steps can I take to address a malfunctioning three-point hitch on my John Deere 7420?

Perform a visual and hands-on inspection of the stepper motor and its connections. Manually adjust the stepper motor if necessary and observe if the error codes relating to the hitch’s operation reappear after being cleared. Persistent error codes might indicate a need for replacement parts or further electrical diagnostics.

What are some electrical and sensor failures I might see with my John Deere 7420 and how can I correct them?

Electrical and sensor issues can manifest as inactive PTO, incorrect dashboard indicators, or recurring overheating messages without an apparent mechanical cause. Systematically check all potential fault points including sensors, stepper motors, and electrical circuits. Clearing and monitoring of error codes, as well as close examination of motor coils or wiring, are crucial steps for proper diagnostics and resolution.

Can you suggest any tips for effective fuel system maintenance for my John Deere 7420?

Regularly replace fuel filters and ensure that the fuel lines are free from air and blockages. It’s also advisable to monitor and maintain the cleanliness of fuel injectors. If your tractor is equipped with specific fuel pumps like Lucas or Stanadyne, refer to the manufacturer’s guidelines for maintenance procedures specific to those systems.

How can I troubleshoot tractor performance issues related to John Deere 7420 troubleshooting?

Tractor performance issues can be due to a range of factors. Start with a thorough examination of the fuel, cooling, hydraulic systems, and electrical components. Diagnose the problem using error messages and codes when available, and consider using a diagnostic scanner for a comprehensive electrical system check. Addressing specific symptoms and patterns of failure can help pinpoint the exact problem for more effective troubleshooting.

Leave a Reply