When heavy-duty farm equipment encounters a standstill, it’s often due to hydraulic issues that can put a pause on productivity. John Deere, a titan in the industry, is no stranger to such challenges. Despite the global recognition for their durable and reliable tractors, owners may sometimes find themselves grappling to troubleshoot tractor hydraulics. It is in times like these that understanding the nuances of your agricultural companion becomes vital to maintaining its uninterrupted service.

Whether it’s due to normal wear and tear or an unforeseen hiccup, resolving John Deere hydraulic issues calls for a strategic approach. The journey of troubleshooting encompasses checking the minutiae such as oil levels, oil viscosity, and the condition of the reservoir air vent cap. These preliminary checks are crucial stepping stones to ensuring the robustness of your machinery doesn’t wane with time.

Through diligent observation and taking corrective actions such as refilling oil, swapping filters, and overhauling exhausted components, your dependable farm equipment will once again rise to the occasion. Let’s delve into a seamless step-by-step method to safeguard and amplify the operability of your John Deere tractors.

Key Takeaways

- Identify and troubleshoot John Deere hydraulic issues to minimize downtime.

- Regular checks of oil levels, viscosity, and air vent caps are essential for smooth operation.

- Address low system pump oil flow by investigating pump inlet lines and relief valves.

- Lubricating linkage and inspecting for bent cylinder shafts can prevent sluggish boom arm movement.

- Proactive maintenance and repair ensure longevity and efficiency of heavy-duty farm equipment.

Understanding Your John Deere Tractor’s Hydraulic System

The robustness of any John Deere tractor is greatly attributed to its advanced hydraulic system, a mainstay in promoting the efficient operation of agricultural equipment. A firm grasp of how these systems function and how to maintain them is imperative for any operator or farm manager. By prioritizing agricultural equipment maintenance, including diligent hydraulic fluid management, longevity and optimal performance of these machines are assured.

It’s through the veins of the John Deere hydraulic system where the lifeblood of tractor operations flow — pressing on with the muscle to lift, push, and maneuver. Let’s peel back the layers to reveal the critical components of this system and lay down the essential groundwork for troubleshooting and upkeep.

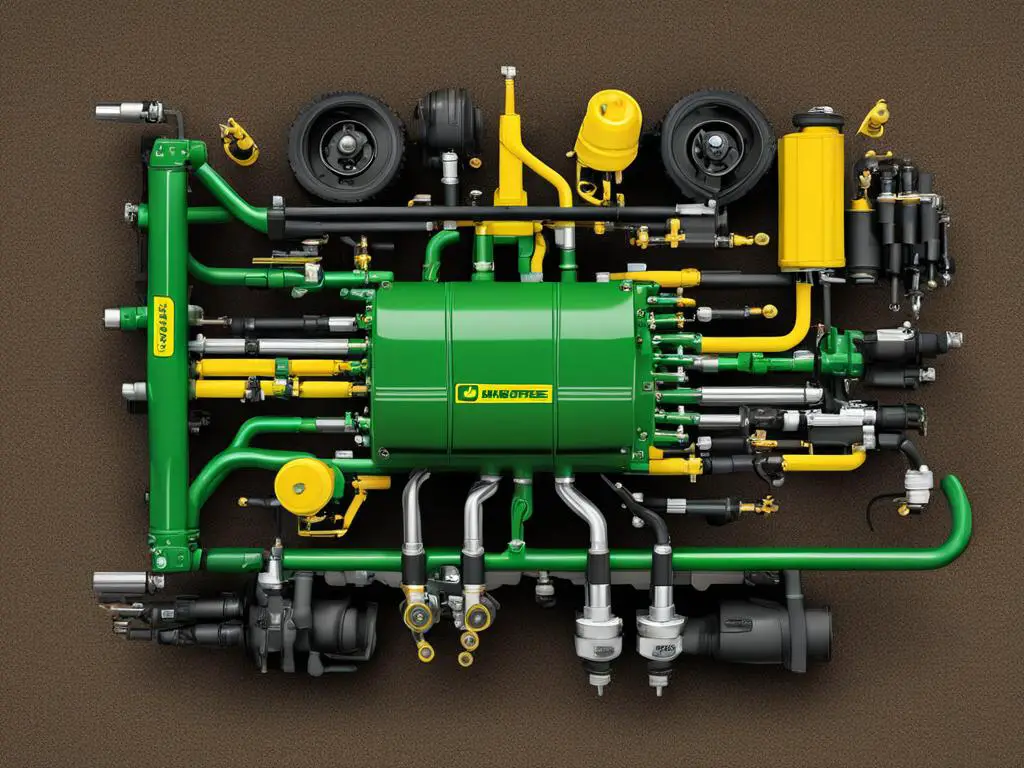

Basic Components and Function

At the heart of the tractor’s hydraulic system are several key components: the system pump, the reservoir, hydraulic cylinders, and an array of control valves. Each has a role in converting the mechanical power of the engine into hydraulic energy that performs vital tasks — from precise steering to the powerful lifting of heavy loads through controlled pressurized fluid. Understanding these components is the foundation for adeptly navigating any maintenance or troubleshooting scenario.

Maintenance Checks Before Troubleshooting

To thwart potential issues in their tracks, seasoned operators know that preventive checks rival reactive repairs. Regularly assessing oil levels, securing line connections, and verifying that the reservoir air vent cap is clear of debris can circumvent a host of problems down the line. When practiced regularly, these checks are your first line of defense in hydraulic fluid management, ensuring that the system’s rhythm isn’t unexpectedly interrupted.

Identifying Common Hydraulic Fluid Issues

Many hydraulic system hiccups stem from fluid-related issues. Be it contamination infiltrating the system or oil viscosity that doesn’t match operating requirements, such inconsistencies can impair functionality. Furthermore, low oil temperatures or levels frequently lead to a lethargic operation, signaling the need for a detailed system inspection. During such reviews, oil changes or filter replacements may be deemed necessary to rejuvenate your John Deere’s performance.

By adhering to a routine steeped in attentive observation and preemptive care, the John Deere hydraulics system will remain a reliable force in your agricultural equipment fleet. With hands-on familiarity of these systems, tailored troubleshooting becomes less of an enigma and more of a strategic response to preserving the vitality of your machinery.

Next, join us for an exploration of how to methodically diagnose issues, ensuring efficient operation continues to be the hallmark of your John Deere tractor.

Step-By-Step Diagnosis of Hydraulic Issues

Delving into hydraulic problem diagnosis for a John Deere tractor begins with a meticulous step-by-step troubleshooting process. Recognizing early symptoms of trouble in your equipment is pivotal to maintaining efficient tractor operation and minimizing unproductive downtime. Here’s a logical and structured approach to identifying and resolving common hydraulic system complications.

Firstly, observe for clinical signs such as sluggishness in operation, abnormal vibrations, or the tractor creeping when it should remain stationary. These indicators signal the need for a thorough inspection.

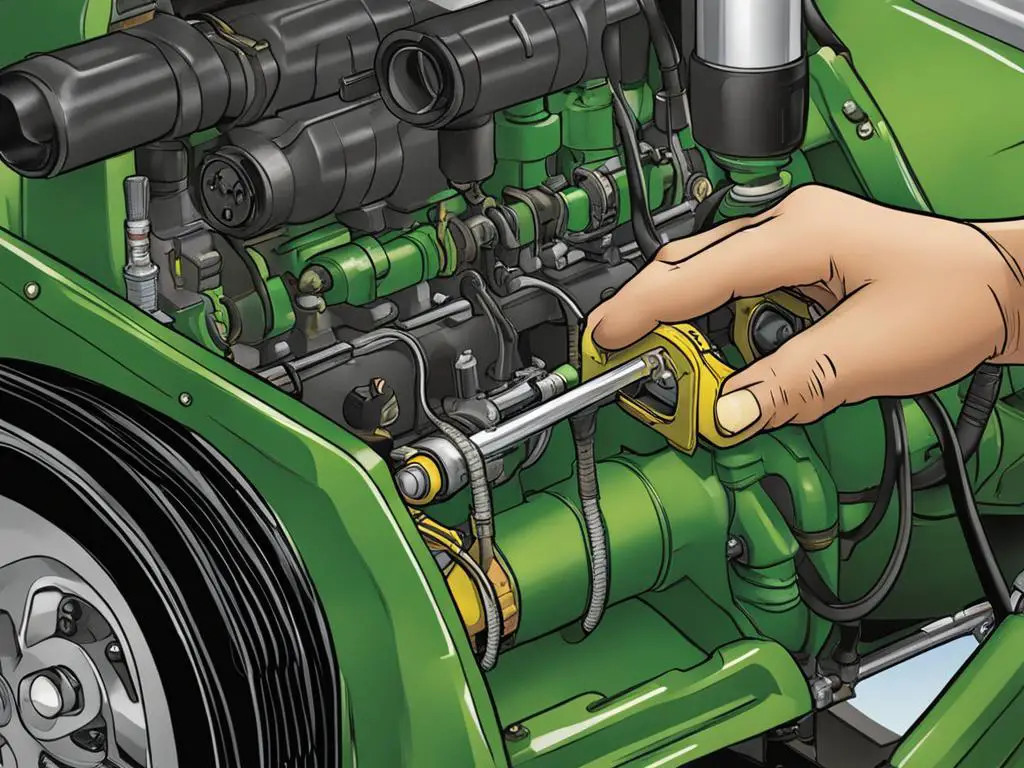

Commence the troubleshooting with a simple yet critical step: checking the hydraulic oil level. Utilize a dipstick or sight glass to gauge if the oil is at the recommended mark. Low levels often precipitate a plethora of hydraulic issues and are the starting point of your investigation.

Next, conduct a sweep for potential leaks. This is a vital step in hydraulic problem diagnosis. Leaks typically manifest around hoses, fittings, reservoirs, or gaskets. Should you discover any, promptly tightening loose fixtures and replacing damaged parts will prevent further complications.

Following the visual inspection, it’s crucial to verify system pressure. Employ a pressure gauge to authenticate if the system operates within the specifications. Anomalies in pressure readings could denote deeper issues within the hydraulic circuitry.

Uneven or insufficient oil flow is another common culprit in hydraulic malfunction. Confirm that the oil flow is in line with your tractor model’s requirements. In cases where the hydraulics fail to maintain the prescribed motor speed or when the Selective Control Valve ceases to operate normally, zero in on discrete components such as the hydraulic motor, compensator valves, and SCV couplers. Thoroughly examine these parts for wear or malfunction.

| Observation | Possible Cause | Action to Take |

|---|---|---|

| Slow Operation | Low hydraulic oil level | Fill to recommended level |

| Excessive Vibration | Loose fittings or damaged parts | Tighten or replace fittings/parts |

| Machine Creeping | Pressure abnormalities | Adjust hydraulic pressure |

| SCV malfunction | Issues in hydraulic motor or valves | Inspect and remedy motor/valves |

At the end of your step-by-step checks, it’s paramount to verify that the tractor’s hydraulics function as intended. Operate the tractor and monitor the response of the hydraulic system under various loads and operations. Steady and unfluctuating performance post-troubleshooting indicates a successful diagnosis and rectification of the hydraulic system issues.

If you encounter persistent hydraulic problems or irregularities beyond your technical acuity, seeking professional assistance is recommended. An expert technician can offer advanced diagnostic tools and repair services to ensure that your John Deere tractor is back to its peak operating condition.

John Deere Tractor Hydraulics Troubleshooting

Navigating through hydraulic issues with your John Deere tractor doesn’t have to be a daunting task. With a fundamental knowledge of tractor pump maintenance and hydraulic oil management, solving these problems can be straightforward. Here’s how you can systematically address common hydraulic troubles, specifically focusing on low oil complications, foaming, contamination, and valve malfunctions.

Low Hydraulic Oil: Symptoms and Solutions

Consistent hydraulic oil management is essential in preventing reduced efficiency in your machinery. Symptoms like impaired steering capability and ignition difficulties often correlate with low hydraulic oil levels. To remedy this, initiate by confirming oil levels, followed by a thorough inspection for leaks. Where necessary, replenishing the hydraulic system components may resolve the underlying issues. Emphasizing regular maintenance schedules can avert these circumstances, preserving your equipment’s operational readiness.

Dealing with Hydraulic Oil Foaming or Contamination

Foaming or contaminated hydraulic oil impairs tractor effectiveness, frequently leading to decreased tractability. Through vigilant inspection of fluid levels and seal conditions, such detriments can be counteracted. Integrating adequate lubrication protocols may replenish deficient lubrication states, thereby mitigating the foaming issue. Proactive recognition and resolution of these anomalies are part and parcel of comprehensive hydraulic system care.

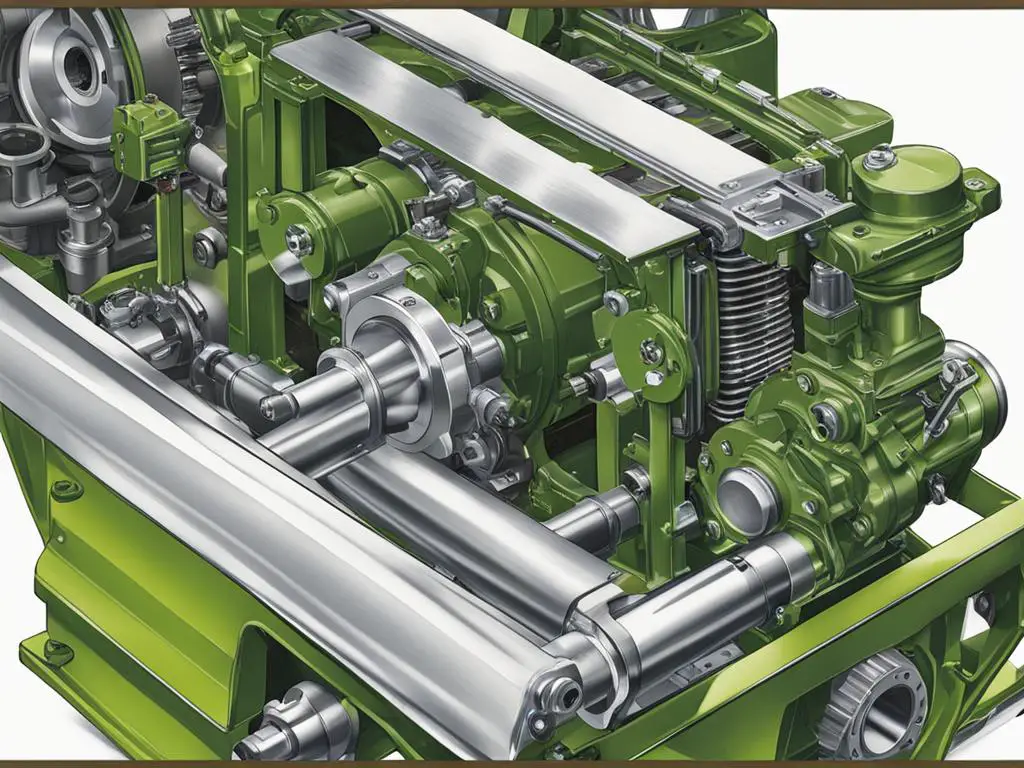

Resolving Hydraulic Pump and Valve Malfunctions

Diagnosing John Deere valve issues and other pump-related malfunctions may manifest through discernible vibrations at operating speeds. Inspecting for wear on hoses, leaks in pumps, or valve deterioration is paramount. It may necessitate replacing or adjusting powertrain components to nullify these vibrational irregularities. A rigorous checkup ensures these key components function optimally, reinstating the tractor’s smooth operation.

| Symptom | Potential Issue | Recommended Action |

|---|---|---|

| Difficulty in steering or engine startup | Low hydraulic oil level | Check and refill oil; inspect for leaks |

| Hydraulic oil foaming | Air entrainment or contamination | Inspect for seal leaks; address lubrication |

| Excessive vibration during operation | Pump or valve malfunctions | Assess and rectify engine or powertrain issues |

| Visible leaks around pump or valves | Worn hoses or fittings | Immediate replacement or repair of damaged parts |

By tackling these troubleshooting measures, you not only restore your John Deere tractor to functionality but also take significant strides in preventing future hydraulic system dilemmas. Understanding the nuances of hydraulic oil management, tractor pump maintenance, and valve upkeep ensures that your equipment remains a durable asset in your agricultural endeavors.

Advanced Troubleshooting for Persistent Hydraulic Problems

When routine maintenance falls short and the ordinary becomes ineffective, advanced troubleshooting methods must be deployed to navigate persistent hydraulic challenges. Recognizing when these sophisticated issues arise is essential for maintaining the performance and longevity of your John Deere tractor. It is at this juncture that the wisdom of specialized care comes into play, guiding the operator to a resolution that ensures the tractor’s stalwart presence in the field.

When to Consult a Professional: Understanding the Limits of DIY

Some complexities of hydraulic systems extend beyond the reach of DIY. When John Deere tractors like the z425, 5055e, or 2950 exhibit symptoms that elude basic troubleshooting, it signals the need for professional intervention. Expertise in professional hydraulic repair becomes invaluable, especially when the challenge at hand calls for a nuanced understanding that only seasoned technicians possess. These trained professionals bring forth the proficiency necessary to resolve intricate issues, ushering your machinery back to its prime condition.

Hydraulic System Calibration and Pressure Testing

Hydraulic system calibration and hydraulic pressure testing represent critical steps in the advanced diagnosis process. Specialized tools and detailed procedures are imperative, as they confirm whether the system meets the specific operational benchmarks for performance and safety. The meticulous nature of these tests, performed within the specialized environments of repair facilities, can highlight discrepancies that often go unnoticed in day-to-day operations, thereby safeguarding against future malfunctions.

Addressing Hydraulic Leaks and Component Wear

Inevitably, with rigorous use, hydraulic components such as valves, pumps, and hoses can succumb to wear or develop leaks. Identifying these issues early on is paramount in preventing extensive damage and ensuring your John Deere tractor remains operational. Precise identification and subsequent repair of these leaks and worn parts seek the cautious hand of a skilled technician. The intricate dance between maintaining and mending forms the bedrock of agricultural productivity, keeping those verdant acres within reach.

FAQ

What are the basic components of a John Deere tractor’s hydraulic system?

The basic components include the hydraulic pump, reservoir, hydraulic cylinders, control valves, and hydraulic lines, all crucial for tasks like steering and lifting.

What maintenance checks are essential before troubleshooting hydraulic issues?

Important maintenance checks include verifying the oil level and quality, ensuring that hose connections are secure, and checking that the air vent cap is clear of obstructions.

How do you identify common hydraulic fluid issues in John Deere tractors?

Common issues with hydraulic fluid include contamination, incorrect oil viscosity, and oil degradation. Identifying these can involve visual inspection and testing of the oil’s properties.

What are the steps to diagnose hydraulic problems in John Deere tractors?

Diagnosis should start with checking the hydraulic oil level, inspecting for leaks, then examining system pressure and flow. It may also include testing control valve operation and pump performance.

What could cause low hydraulic oil levels in my John Deere tractor, and how can I resolve it?

Low hydraulic oil can result from leaks or consumption over time. Resolve by topping up the oil, repairing leaks, and routinely checking oil level as preventive maintenance.

How should I deal with hydraulic oil foaming or contamination?

To address oil foaming or contamination, replace the oil and filter, check for and repair leaks in the system, and ensure you’re using the correct type of hydraulic fluid.

What should I do if I suspect hydraulic pump and valve malfunctions?

Investigate the pump and control valves for proper operation. This may involve visual inspection, listening for unusual noises, and checking for overheating or erratic movement. Repairs or replacements may be needed if issues are found.

When is it time to consult a professional for persistent hydraulic problems on my John Deere tractor?

If basic troubleshooting does not resolve the issue, if specialized diagnostic equipment is needed, or when dealing with complex problems like system calibration, it’s best to consult a professional.

What does hydraulic system calibration and pressure testing involve?

Hydraulic system calibration involves adjusting the system to perform within its specified parameters. Pressure testing checks the system’s ability to maintain pressure at various points and is crucial for ensuring proper function.

How do you address hydraulic leaks and component wear in John Deere tractors?

Addressing leaks and wear includes inspecting all system components for damage, replacing worn parts like seals or hoses, and ensuring that all connections are tight to prevent future leaks.

Leave a Reply