Welcome to our expert guide on the common issues with John Deere 345 tractors. As experienced professionals in the field, we understand the importance of troubleshooting and maintenance to keep your tractor running smoothly. In this article, we will explore some of the problems that owners frequently encounter and provide useful tips to address them effectively. Whether you are experiencing engine oil contamination, hydraulic leaks, steering column overheating, or clutch problems, we have got you covered. Let’s dive into the world of John Deere 345 problems and discover how you can tackle them with confidence.

Engine Oil Contamination

One common problem with the John Deere 345 tractor is engine oil contamination. This can occur when diesel fuel leaks into the crankcase, causing the oil level to increase. The most likely culprits for this issue are a faulty fuel transfer pump or leaking seals on the injector pump drive shaft. It is important to monitor the oil level closely and address any fuel-related smoke or oil consumption.

Engine oil contamination in the John Deere 345 tractor can have detrimental effects on its performance and longevity. The presence of diesel fuel in the crankcase can lead to decreased lubrication and increased wear on engine components. Furthermore, the contaminated oil may not effectively dissipate heat, potentially causing the engine to overheat.

To safeguard the engine and ensure optimal performance, regular oil checks and early detection of oil contamination are crucial. Upon noticing any signs of oil contamination, such as unusual smells or discoloration, immediate action should be taken to identify and resolve the root cause.

“Engine oil contamination due to diesel fuel leakage is a common problem in the John Deere 345 tractor. Timely detection and resolution are essential to prevent further damage to engine components.”

Identifying the Source of Oil Contamination

When faced with engine oil contamination, it is important to identify the source promptly. The two primary culprits responsible for diesel fuel leakage into the crankcase are a faulty fuel transfer pump and leaking seals on the injector pump drive shaft.

Faulty Fuel Transfer Pump

The fuel transfer pump is responsible for delivering fuel from the fuel tank to the injectors. A malfunctioning pump can lead to excessive fuel leakage, allowing diesel fuel to enter the crankcase and contaminate the engine oil. Regular inspection of the fuel transfer pump and prompt replacement or repair can help prevent oil contamination.

Leaking Seals on the Injector Pump Drive Shaft

Another common cause of oil contamination in the John Deere 345 tractor is leaking seals on the injector pump drive shaft. These seals can degrade over time, allowing diesel fuel to seep into the crankcase. Routine inspection of the seals and timely replacement can mitigate the risk of engine oil contamination.

Proactive maintenance, including proper seal lubrication and regular inspection of the fuel transfer pump, can promote early detection and prevention of oil contamination. Furthermore, monitoring the oil level closely and addressing any signs of fuel-related smoke or increased oil consumption can help mitigate the impact of engine oil contamination.

| Signs of Engine Oil Contamination | Possible Causes | Recommended Action |

|---|---|---|

| Unusual oil smells or discoloration | Fuel transfer pump failure | Inspect and replace faulty pump |

| Increased oil level | Leaking seals on injector pump drive shaft | Inspect and replace worn seals |

| Poor engine performance | Decreased lubrication due to oil contamination | Flush and replace contaminated oil |

| Engine overheating | Ineffective heat dissipation caused by contaminated oil | Investigate and resolve cooling system issues |

Hydraulic Leaks

One of the commonly reported issues with the John Deere 345 tractor is hydraulic leaks. Owners have observed strong chatter in the hydraulic lines, particularly at idle, which can become more pronounced during extended usage, such as during hay season. In addition, the hydraulic system is susceptible to overheating, resulting in a loss of hydraulic function. Potential causes of these problems include internal line cracks or blockages.

To address hydraulic leaks in the John Deere 345, it is recommended to inspect and clean the hydraulic coolers regularly. This maintenance practice helps ensure optimal performance and minimizes the risk of leaks. However, if the hydraulic leaks persist despite these efforts, further investigation may be required to identify the root cause of the issue.

Hydraulic Leaks Troubleshooting Tips:

- Inspect the hydraulic lines for any visible cracks or signs of damage.

- Check for blockages in the hydraulic system, such as debris or foreign objects that may impede the flow of hydraulic fluid.

- Monitor the hydraulic oil temperature during operation to identify any potential overheating issues.

- If necessary, consult with a qualified technician or John Deere service center for expert assistance in diagnosing and resolving hydraulic leaks.

By following these troubleshooting steps and addressing hydraulic leaks promptly, John Deere 345 owners can maintain the functionality and longevity of their tractors.

| Possible Causes of Hydraulic Leaks | Recommended Solutions |

|---|---|

| 1. Internal line cracks | – Inspect and repair/replace damaged hydraulic lines – Ensure proper installation and secure connections |

| 2. Blockages in the hydraulic system | – Clean the hydraulic coolers and system components regularly – Remove any debris or foreign objects obstructing the flow of hydraulic fluid |

Steering Column Overheating

The John Deere 345 tractor is known for having a hot steering column, which can be a sign of internal hydraulic issues. When the steering column overheats, it can lead to a loss of power steering function, making it difficult to maneuver the tractor effectively.

One of the most common causes of steering column overheating in the John Deere 345 is leaking seals in the steering valve. These seals can wear out over time and allow hydraulic fluid to escape, leading to increased friction and heat. If left unaddressed, this issue can result in further damage to the steering system.

To prevent or resolve steering column overheating, it is recommended to have the steering valve inspected by a qualified technician. They will be able to identify any leaking seals and determine if a replacement is necessary. By replacing the seals, the proper operation of the steering system can be restored, reducing the risk of overheating and ensuring smooth maneuverability while operating the tractor.

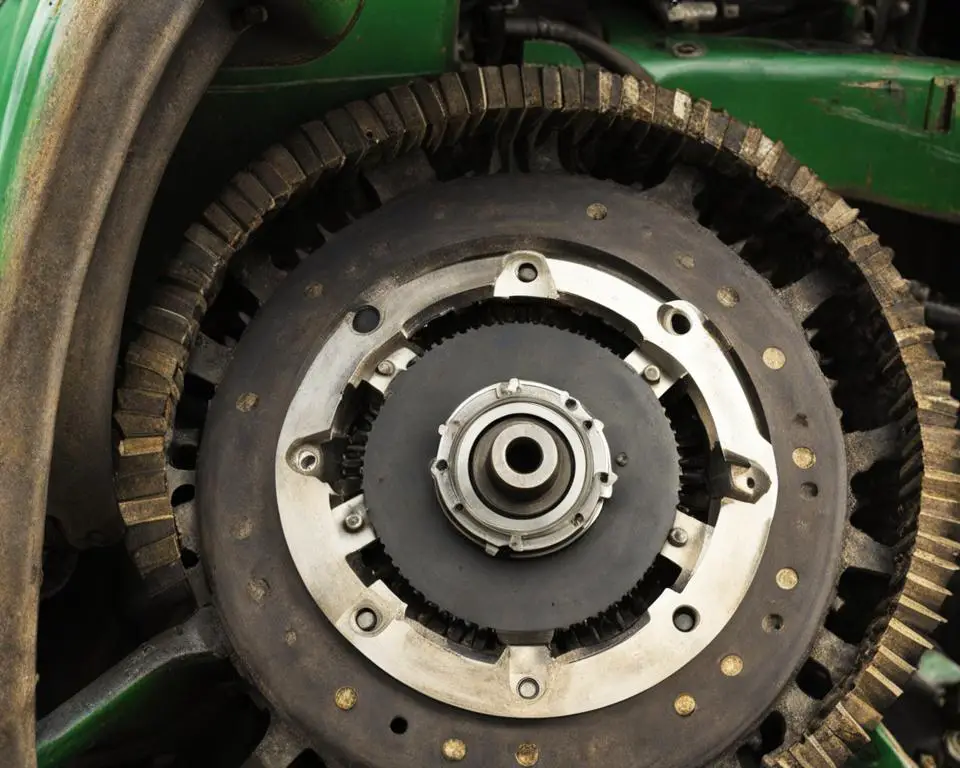

Clutch Problems

Clutch problems can be a common occurrence among owners of the John Deere 345 tractor. While not exclusive to this particular model, clutch issues can often arise due to normal wear and tear or improper use. It is important for owners to promptly address clutch problems to prevent any further damage to the transmission and ensure the tractor operates smoothly.

One of the most noticeable signs of a clutch problem is when it starts slipping or fails to engage properly. This can result in a significant decrease in power, reduced efficiency, and potential damage to other components of the tractor. If you experience any of these issues, it may be necessary to replace the clutch.

Clutch replacement involves removing the old clutch assembly and installing a new one that is compatible with the John Deere 345 tractor. It is recommended to consult the tractor’s manual or seek professional assistance to ensure the correct replacement clutch is chosen.

When selecting a replacement clutch, it is important to consider the specific needs of your tractor and usage. Different types of clutches are available, such as organic or synthetic material clutches, and it is essential to choose one that is suitable for your tractor’s requirements.

In addition to clutch replacement, proper clutch maintenance is crucial to ensure its longevity and optimal performance. Regular inspection of the clutch system, including the clutch pedal, linkage, and release mechanism, is recommended to identify any potential issues early on. Lubricating the clutch components as per the manufacturer’s recommendations can also help prevent premature wear and ensure smooth clutch operation.

Overall, addressing clutch problems promptly and following proper maintenance practices can effectively resolve issues and improve the performance of the John Deere 345 tractor.

| Common Signs of Clutch Problems | Potential Causes |

|---|---|

| Clutch slipping | Worn clutch plate |

| Difficulty shifting gears | Maladjusted clutch linkage |

| Clutch not engaging properly | Worn pressure plate |

| Burning smell from the clutch | Clutch plate overheating |

Troubleshooting and Maintenance Tips

To address the common problems with the John Deere 345 tractor, owners can follow some troubleshooting and maintenance tips. By regularly monitoring the oil level and checking for any signs of oil contamination, you can catch potential issues early on. Inspecting the hydraulic system for leaks, cleaning the coolers, and checking for any blockages is also crucial to ensure optimal performance.

If you are experiencing steering column overheating, it is recommended to seek professional assistance for valve and seal replacement. This will help address the root cause of the problem and prevent further damage. Additionally, addressing clutch problems promptly is essential. If you notice any signs of clutch failure such as slipping or improper engagement, consider replacing the clutch to maintain the tractor’s performance.

Regular Maintenance Checklist:

- Monitor oil level and check for oil contamination

- Inspect hydraulic system for leaks

- Clean hydraulic coolers and check for blockages

- Seek professional assistance to address steering column overheating

- Promptly address clutch problems and consider clutch replacement if necessary

By following these troubleshooting and maintenance tips, you can keep your John Deere 345 tractor in top condition and ensure its longevity. Regular maintenance not only helps prevent common issues but also contributes to the overall reliability and performance of your tractor.

Expert Advice for John Deere 345 Owners

As an owner of a John Deere 345 tractor, it’s crucial to stay proactive in your maintenance and repairs to ensure optimal performance and longevity. Experts recommend following the manufacturer’s guidelines and regularly servicing your tractor, including regular oil and filter changes. By doing so, you can prevent many issues from arising and keep your tractor in top condition.

However, even with proper maintenance, problems can still occur. That’s why it’s important to address any issues promptly to prevent further damage or costly repairs. Ignoring a small problem can quickly escalate into a more significant and expensive issue. So, if you notice any unusual sounds, smells, or performance changes, it’s best to take action right away.

Consulting with a qualified technician or seeking advice from knowledgeable sources can provide valuable insights for addressing specific maintenance and repair needs. These experts have the experience and know-how to diagnose and fix problems efficiently, saving you time and money in the long run.

“Seeking expert advice when in doubt can make a world of difference in maintaining the performance and reliability of your John Deere 345 tractor.”

Whether it’s troubleshooting a persistent issue or seeking guidance for routine maintenance, tapping into the expertise of professionals and fellow owners can provide invaluable support and knowledge. Online forums, user groups, and manufacturer resources are excellent places to connect with others who have faced similar challenges.

Here are some expert tips to keep in mind:

- Follow the manufacturer’s recommended maintenance schedule.

- Regularly inspect and replace worn-out parts.

- Pay close attention to any changes in performance, such as strange noises or decreased power.

| Expert Advice for John Deere 345 Owners | Maintenance Tips | Repairs |

|---|---|---|

| Regularly service your tractor according to the manufacturer’s guidelines. | Inspect and replace worn-out parts to prevent further damage. | Address any problems promptly to avoid more expensive repairs. |

| Consult with a qualified technician for proper diagnosis and repair. | Monitor performance changes and address them promptly. | Seek advice from knowledgeable sources for specific issues. |

Conclusion

The John Deere 345 tractor, despite its common problems, can still be a reliable machine with proper maintenance and care. By being aware of these common issues and taking prompt action when they arise, owners can ensure their tractors run smoothly and efficiently. Regular inspections, troubleshooting, and maintenance are key to maximizing the longevity and performance of the John Deere 345.

When it comes to the John Deere 345, prevention is better than cure. Owners should regularly monitor the oil level, checking for any signs of contamination. Additionally, inspecting the hydraulic system for leaks, cleaning the coolers, and addressing any blockages can help avoid more significant issues down the line. If the steering column overheats persistently, seeking assistance from qualified technicians for valve and seal replacement is recommended.

Lastly, clutch problems should not be overlooked. Clutch replacement may be necessary if symptoms such as slipping or improper engagement occur. Acting promptly can prevent further damage to the transmission and ensure optimum performance. Following these maintenance and troubleshooting tips will help John Deere 345 owners keep their tractors in top condition and minimize downtime.

FAQ

What are some common issues with John Deere 345 tractors?

Common issues with John Deere 345 tractors include engine oil contamination, hydraulic leaks, steering column overheating, and clutch problems.

What causes engine oil contamination in John Deere 345 tractors?

Engine oil contamination in John Deere 345 tractors can be caused by diesel fuel leaking into the crankcase. This can occur due to a faulty fuel transfer pump or leaking seals on the injector pump drive shaft.

What are some signs of hydraulic leaks in John Deere 345 tractors?

Signs of hydraulic leaks in John Deere 345 tractors include strong chatter in the hydraulic lines at idle and a loss of hydraulic function. Hydraulic overheating can also occur during prolonged use.

Why does the steering column overheat in John Deere 345 tractors?

The steering column in John Deere 345 tractors can overheat due to leaking seals in the steering valve. This can lead to a loss of power steering function.

What are some common clutch problems in John Deere 345 tractors?

Common clutch problems in John Deere 345 tractors include slipping, improper engagement, and signs of failure. These issues can arise due to normal wear and tear or improper use.

What troubleshooting and maintenance tips can help address the common problems in John Deere 345 tractors?

To address the common problems in John Deere 345 tractors, owners can monitor the oil level for any signs of contamination, inspect and clean the hydraulic system, and promptly address steering column overheating and clutch problems.

What expert advice can help John Deere 345 owners with maintenance and repairs?

Experts recommend that John Deere 345 owners regularly service the tractor according to the manufacturer’s guidelines, address any problems promptly, and seek assistance from qualified technicians or knowledgeable sources for optimal tractor performance.

How can proper maintenance and care contribute to the performance of John Deere 345 tractors?

With proper maintenance and care, John Deere 345 tractors can continue to be reliable machines. Regular inspections, troubleshooting, and maintenance will contribute to their longevity and performance.

Leave a Reply