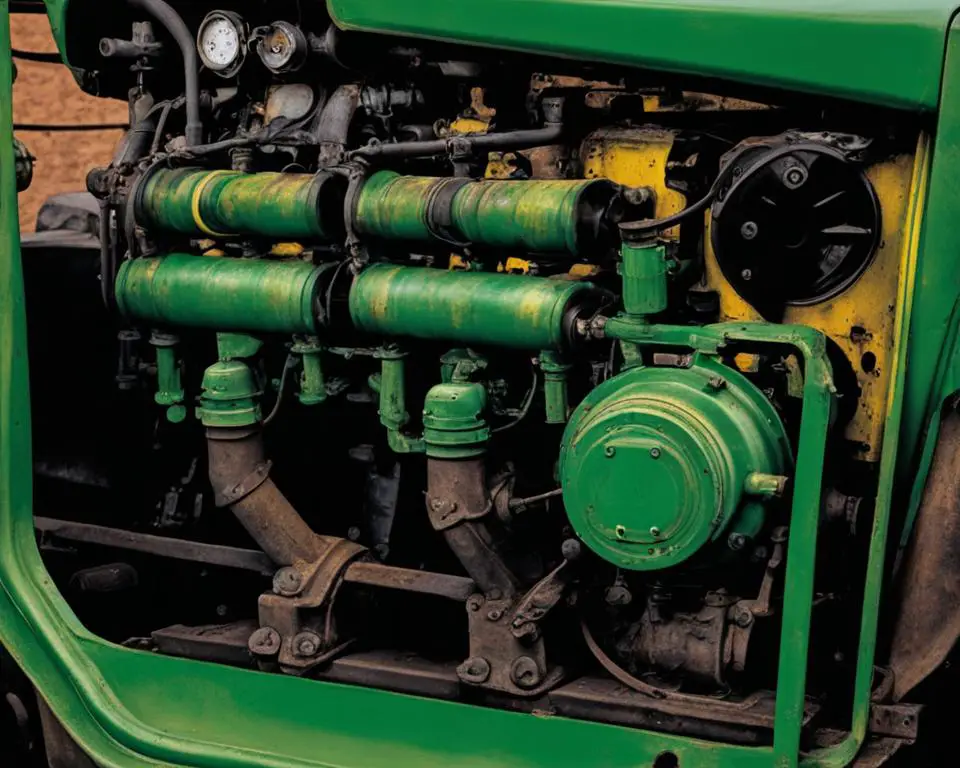

When it comes to maintaining your John Deere 2440 tractor’s performance, it’s crucial to be aware of common problems and address them promptly. From hydraulic issues to engine troubles, staying proactive can save you from costly repairs and downtime.

In this article, we will explore the most common issues that 2440 owners may encounter, including coolant electrolysis, loss of hydraulics, starting difficulties, and other minor concerns. By understanding these problems and implementing the necessary maintenance, you can ensure your John Deere 2440 operates smoothly and efficiently.

Let’s dive into the details and find out how you can address these common issues and maintain your tractor’s performance

.Coolant Electrolysis and Sleeve Corrosion

Coolant electrolysis is a known problem in older John Deere tractors, including the 2440 model. This occurs when the pH of the coolant is not properly maintained or if there is a lack of coolant treatment. The electrolysis can cause sleeve corrosion, which can lead to engine damage and expensive repairs. It is important to regularly check the coolant pH and use a coolant treatment to prevent this problem. Additionally, conducting oil tests and analyzing the coolant can provide early indications of coolant electrolysis and sleeve corrosion.

One way to address coolant electrolysis and prevent sleeve corrosion is by regularly monitoring the pH level of the coolant. Ideally, the pH should be within the manufacturer’s recommended range. If the pH is too high or too low, it can accelerate the electrolysis process and increase the risk of sleeve corrosion. By regularly testing the coolant pH and adjusting it as needed, owners can mitigate the risk of coolant electrolysis and protect the engine from potential damage.

Another preventive measure is the use of a coolant treatment. Coolant treatments are designed to inhibit the electrolysis process and protect the engine components from corrosion. These treatments typically contain additives that neutralize the acid produced during electrolysis, maintaining the pH balance of the coolant. By adding a coolant treatment according to the manufacturer’s recommendations, tractor owners can further safeguard their engine against sleeve corrosion caused by coolant electrolysis.

Regular oil tests and coolant analysis can also provide valuable insights into the presence of coolant electrolysis and potential sleeve corrosion. Oil tests can detect the presence of coolant in the engine oil, indicating a coolant leak and potential sleeve corrosion. Similarly, analyzing the coolant for any signs of contamination or abnormal levels of corrosion-related elements can help identify early stages of sleeve corrosion. By conducting these tests periodically, owners can catch and address coolant electrolysis before it leads to costly damage and repairs.

| Signs of Coolant Electrolysis and Sleeve Corrosion | Preventive Measures |

|---|---|

| Engine overheating | Regularly check and adjust coolant pH |

| Coolant leaking into engine oil | Use a coolant treatment as recommended |

| Increased coolant consumption | Conduct oil tests for early detection |

| Poor engine performance | Analyze coolant for signs of corrosion |

Loss of Hydraulics

Loss of hydraulics can be a frustrating issue for owners of John Deere 2440 tractors. This problem is often caused by issues with the PTO clutch or brake lines. Improper installation, leaks, or damage to these components can result in a loss of hydraulic function, affecting the tractor’s performance and functionality. To prevent and address such issues, it is crucial to ensure that the PTO clutch and brake lines are properly connected and functioning correctly.

Regular inspections and maintenance play a vital role in detecting any potential problems with the hydraulics system. By conducting routine checks, owners can identify leaks, worn-out parts, or other issues that may affect the performance of the hydraulic system. Addressing these problems proactively can prevent further damage and costly repairs in the long run.

Common Causes of Loss of Hydraulics

Loss of hydraulics in John Deere 2440 tractors can be attributed to several factors, including:

- Poor installation of the PTO clutch or brake lines.

- Leaking or damaged brake lines.

- Worn-out components in the hydraulic system.

- Inadequate maintenance and neglect.

Addressing these causes requires proper troubleshooting and repair techniques. Owners should consult the tractor’s manual or seek assistance from qualified technicians to diagnose and resolve the issues effectively.

Preventing Loss of Hydraulics

To prevent the loss of hydraulics in John Deere 2440 tractors, owners can follow these maintenance tips:

- Regularly inspect the PTO clutch and brake lines for leaks, cracks, or damage.

- Ensure proper installation of the PTO clutch and brake lines.

- Perform routine maintenance on the hydraulic system, including fluid checks and filter replacements.

- Adhere to the recommended maintenance schedule provided by John Deere.

- Monitor the tractor’s performance and address any signs of hydraulic trouble promptly.

Starting Issues and Hot Start Pressure Relief Valve

Starting issues can occasionally arise with the John Deere 2440 tractor, especially in colder conditions. One contributing factor to these challenges is the presence of a hot start pressure relief valve on some 2440 tractors. This valve, when improperly adjusted or experiencing issues, can make starting the tractor more difficult. A hard starting problem may emerge as a result. It may be necessary to destroke the front pump or adjust the valve to facilitate easier starting.

Regular maintenance and inspections are critical for identifying and addressing any starting issues that may arise. By proactively addressing these concerns, tractor owners can ensure a smoother and more reliable starting experience for their John Deere 2440.

John Deere 2440 Starting Issues Troubleshooting Tips:

- Inspect and adjust the hot start pressure relief valve according to the manufacturer’s guidelines.

- Check the front pump for proper destroking to enable easier starting.

- Examine the starter and battery to ensure they are in good working condition.

- Verify that the fuel system is clean and free of any blockages.

Addressing starting issues promptly can help avoid frustrating delays and potential damage to your John Deere 2440 tractor.

Regular maintenance and adherence to the manufacturer’s recommended practices can significantly reduce starting issues and ensure optimal performance.

| Common Starting Issues | Possible Causes | Recommended Solutions |

|---|---|---|

| Hard starting | Improper hot start pressure relief valve adjustment Front pump not destroked correctly | Adjust the hot start pressure relief valve Ensure proper destroking of the front pump |

| Intermittent starting | Faulty starter Weak or discharged battery | Replace the starter if necessary Charge or replace the battery |

| No start | Fuel system blockage Ignition system failure | Clean or replace any clogged fuel filters Inspect and repair the ignition system components as needed |

Conclusion

The John Deere 2440 tractor, known for its reliability, is not exempt from common problems that owners should be aware of. To ensure optimal performance and longevity, it is crucial to address these issues promptly and perform regular maintenance. Some of the common problems that can arise with the John Deere 2440 include coolant electrolysis and sleeve corrosion, loss of hydraulics, starting issues with the hot start pressure relief valve, as well as minor concerns like shifter and parking brake wear.

By taking a proactive approach, owners can maintain the performance of their John Deere 2440 tractor and avoid expensive repairs. Regular inspections, proper maintenance, and the use of genuine John Deere parts are key. Addressing common issues like coolant electrolysis and sleeve corrosion through coolant pH checks and the use of coolant treatment can prevent engine damage. Ensuring proper installation and maintenance of the PTO clutch, brake lines, and hot start pressure relief valve can help avoid loss of hydraulics and starting issues.

To maintain the optimal function and longevity of the John Deere 2440 tractor, it is essential to stay proactive, perform regular maintenance, and promptly address common problems. By doing so, owners can ensure that their John Deere 2440 continues to perform at its best, avoiding costly repairs and maximizing its lifespan.

FAQ

What are the common issues with the John Deere 2440 tractor?

The common issues with the John Deere 2440 tractor include coolant electrolysis and sleeve corrosion, loss of hydraulics, starting issues with the hot start pressure relief valve, and minor concerns like shifter/parking brake wear and fuel tank rust.

What is coolant electrolysis and how does it affect the tractor?

Coolant electrolysis is a problem that can occur in older John Deere tractors, including the 2440 model. It happens when the pH of the coolant is not properly maintained or if there is a lack of coolant treatment. This electrolysis can cause sleeve corrosion, leading to engine damage and expensive repairs. Regularly checking the coolant pH and using a coolant treatment can help prevent this problem.

How can I prevent a loss of hydraulics in my John Deere 2440 tractor?

To prevent a loss of hydraulics, it is important to ensure that the PTO clutch and brake lines are properly installed and functioning correctly. Regular inspections and maintenance can help identify and address any issues before they become more significant problems.

What can I do if I’m experiencing starting issues with my John Deere 2440 tractor?

If you are experiencing starting issues, especially in colder conditions, it may be due to the hot start pressure relief valve. Adjusting the valve or destroking the front pump can help facilitate easier starting. Regular maintenance and inspections can help identify and address any starting problems.

How should I address the minor concerns with my John Deere 2440 tractor?

Minor concerns like shifter/parking brake wear and fuel tank rust can be addressed by promptly conducting inspections and maintenance. By staying proactive and addressing these common issues, owners can maintain their John Deere 2440 tractor’s performance and avoid costly repairs.

Leave a Reply