For every ardent operator of the iconic John Deere 7600, navigating the pitfalls of repair and maintenance is a key aspect of ownership. Known for its robust performance and agricultural efficiency, this staple of farming machinery isn’t immune to mechanical challenges. Engaging in regular John Deere 7600 repairs and preventive agricultural machinery maintenance is paramount to ensuring the powerquad transmission’s longevity and smooth operation. Whether it’s a nuanced clutch calibration procedure or an intricate engine overhaul, comprehending the inner workings of this machine is invaluable for continuous productivity on the farm.

Understanding the subtle signs of wear and the know-how for timely interventions can avert the inconvenience of unexpected downtime. When the clutch presents issues, especially in ranges B, C, and D, with a failure to engage smoothly resulting in abrupt tractor jerks, it’s a clear call for maintenance action. Such symptoms suggest a possible need for intricate repairs, igniting inquiries about the complexity involved in replacing friction discs and the art of clutch calibration. Implementing precise solutions, from diagnostics to comprehensive repairs, ensures the powerhorse that is the John Deere 7600 remains a relentless force in agriculture’s demanding arena.

Key Takeaways

- Timely John Deere 7600 repairs are critical to avert sigificant downtime.

- Understanding clutch issues and their appropriate fixes directly correlates with better tractor performance.

- Proactive agricultural machinery maintenance is key to avoiding complex repairs.

- Familiarity with powerquad transmission operations facilitates effective troubleshooting.

- Having a grasp on the proper procedure of clutch calibration is essential for smooth gear engagement.

- Conducting an engine overhaul might be necessary for high-hour engines to maintain tractor efficiency.

Identifying Common John Deere 7600 Transmission Issues

Owners of the John Deere 7600 series may at times encounter challenges with tractor transmission, which can affect the quality and efficiency of their farm operations. A range of common issues including problems with powerquad transmissions, difficulty in smooth gear shifting, and the need for clutch pack replacement are often reported. Addressing these concerns is vital for ensuring that the tractor performs its tasks effectively.

One of the core aspects of tractor diagnostics is identifying wear or damage to the tractor’s critical components. Notably, the clutch packs can exhibit signs of wear after extensive use, particularly if the tractor has been heavily engaged in tasks requiring high power output. When diagnosing transmission-related issues, John Deere 7600 transmission repair experts examine specific elements like piston ring condition and the integrity of the high-pressure fuel pump drive shaft.

Conducting a thorough diagnostic is the first step towards resolving these issues. Let’s take a closer look at the types of transmission problems and their possible remedies:

- Difficulties in gear shifting: This problem may manifest as resistance or jerkiness when shifting gears, indicating the potential need for a clutch pack review or replacement.

- Clutch engagement issues: If the tractor fails to engage smoothly across various ranges, it could be a sign that the clutch calibration needs to be examined.

In the table below, we summarize common transmission problems and their potential fixes:

| Issue | Signs and Symptoms | Possible Fix |

|---|---|---|

| Worn Clutch Pack | Difficulty engaging gears, especially after significant usage hours. | Clutch pack replacement. |

| Piston Ring Wear | Decrease in power, transmission slipping. | Inspection and possible overhaul of affected components. |

| Fuel Pump Drive Shaft Issues | Hard starting engine, inconsistent power delivery. | Checking and potentially replacing the high-pressure fuel pump drive shaft. |

Addressing these transmission issues efficiently is crucial for the longevity and reliability of the John Deere 7600 tractor. Skilled mechanics, equipped with the right tools and knowledge, are best suited to handle these repairs, as they often necessitate intricate work and a thorough understanding of the tractor’s transmission system. Despite the complexity, successful transmission repairs can restore and even enhance the tractor’s performance, ensuring a continuity of smooth operation on the farm.

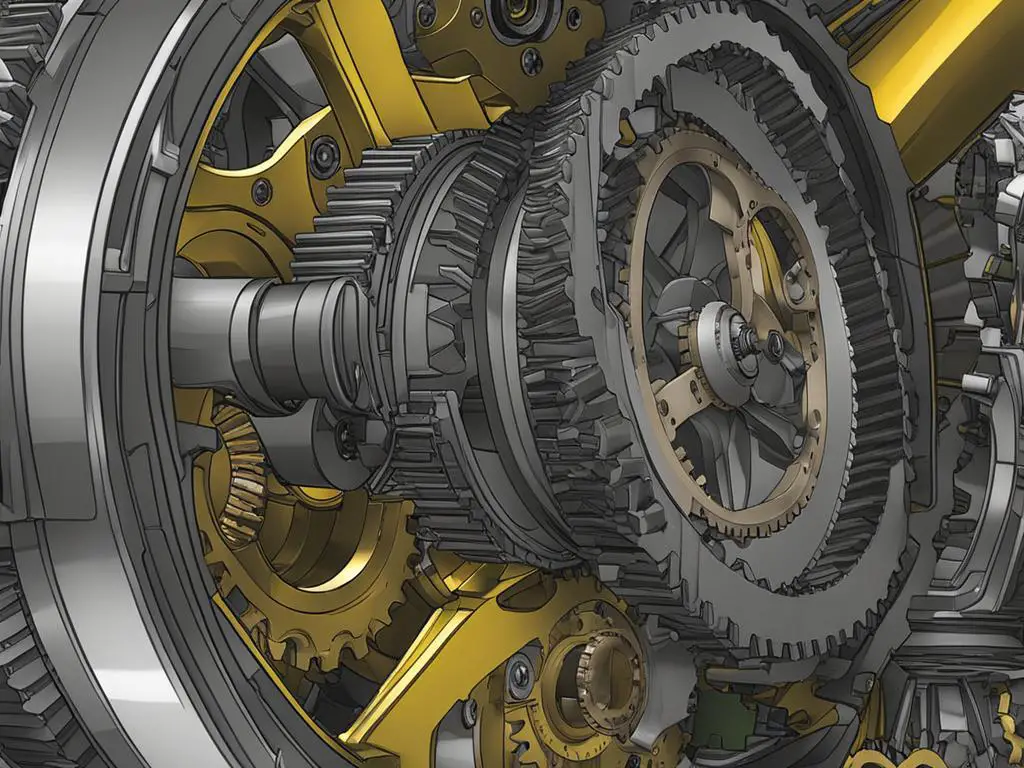

For your reference, here is a visual guide that can help you identify signs of transmission wear:

The key to sustained tractor performance is early detection and precise intervention. Therefore, regular check-ups and proactive maintenance are recommended in order to avoid powerquad issues and to maintain smooth gear shifting on your John Deere 7600.

John Deere 7600 Hydraulic System Malfunctions

Agricultural productivity hinges on the consistent performance of the John Deere 7600’s hydraulic system, but farmers often face setbacks due to faults such as John Deere 7600 steering problems and other hydraulic component failures. From rigorous hydraulic oil maintenance to the more involved process of steering cylinder seal replacement, staying ahead of these issues ensures the tractor operates as intended. Let’s delve into the common hydraulic system challenges and their practical solutions.

Steering Challenges and Fluid Levels

Dealing with hydraulic system troubleshooting begins by addressing the tractor’s vital steering function. Insufficient hydraulic fluid levels frequently lead to compromised steering response, which can be alleviated through vigilant hydraulic oil maintenance. The seamless operation of the steering system is foundational to maneuvering and precision in the field; thus, prompt attention is imperative to ensure control is maintained.

Hydraulic Pump and Cylinder Failures

When reporting instances of hard steering or complete steering failure, it could be indicative of pressing issues within the hydraulic system components. A failing hydraulic pump is a critical concern, often necessitating comprehensive John Deere hydraulic pump repair. Similarly, tractor cylinder issues might call for steering cylinder seal replacement, requiring technical expertise and stringent adherence to repair protocols.

Issues with Differential Lock and Brakes

Operation of the John Deere 7600 may be hindered by differential lock malfunction and John Deere 7600 brake repairs. Friction clutch disk anomalies and diaphragm tears undermine the operation of differential locks, while brake delays or failures might signal an urgent need for maintenance, potentially expanding to a comprehensive system overhaul to prevent further agricultural delays and equipment damage.

For seasoned farmers and repair technicians alike, understanding these common malfunctions and their resolution methods is vital for keeping the beloved John Deere 7600 operational. Addressing differential lock malfunction, clutch disk issues, and ensuring well-maintained brakes play a pivotal role in avoiding breakdowns that impact both time and resources on the farm.

John Deere 7600 Problems: Engine and Electrical Concerns

For farmers who rely on the John Deere 7600, confronting engine start issues and electrical complications can disrupt a day’s work on the field. Ensuring optimal functionality involves delving into each subsystem with a meticulous approach towards diesel system maintenance and John Deere electrical troubleshooting

. This section examines common engine and electrical concerns, strategies for maintenance, and potential remedies that are pivotal for tractor performance.Engine Starting Difficulties and Diesel System Blockages

Engine start issues in the John Deere 7600 can be multi-faceted, ranging from restricted fuel lines to water contamination in fuel. Farmers must prioritize routine fuel line checks and effective diesel system maintenance to prevent these problems. Immediate intervention such as fuel system flushes or filter replacements could be all that’s needed to rectify these starting difficulties.

- Air filters: An obstructed air filter can suffocate the engine, leading to startup failure. Regular inspection and cleaning are essential.

- Fuel system airlocks: Air trapped in fuel lines impedes diesel flow, calling for de-airing procedures.

Ignition System Failures and Valve Adjustment

When electrical issues arise, operators must engage in John Deere electrical troubleshooting to isolate the fault. Ignition system repairs, including addressing spark plug dysfunction and ignition system repair, are among the typical fixes. Additionally, the precision of valve timing adjustments is critical to prevent misfires and ensure smooth engine performance.

Overheating and Exhaust Troubles

Engine overheating poses significant challenges, often requiring immediate attention to John Deere 7600 overheating solutions. This may include strategies such as exhaust system checks and diligent radiator maintenance. An overheated engine should prompt an exhaustive examination of the cooling system to identify potential blockages or leaks.

Resolving exhaust and overheating issues often involves tackling symptoms like white smoke, which could suggest the need for engine overhaul due to compromised piston rings. Below is a summary of standard engine and cooling system checks to manage these problems:

| Critical Checkpoint | Potential Issue | Recommended Action |

|---|---|---|

| Fuel and Air System | Contamination, blockages, airlocks | Systematic cleaning, filter replacement, de-airing |

| Ignition System | Component wear, improper timing | Timing adjustments, component replacements |

| Cooling System | Depleted coolant, obstructions | Coolant refill, radiator cleaning |

To forestall engine and electrical dilemmas on your John Deere 7600, adhering to a strict maintenance regimen is essential. Farmers must balance hands-on diagnostics with professional servicing to exploit the full potential of their equipment for sustained agricultural productivity.

Conclusion

Maintaining agricultural equipment efficiency is crucial for any farming operation, and for those utilizing the workhorse that is the John Deere 7600, understanding and mitigating its potential problems ensures just that. Optimizing John Deere 7600 performance requires a proactive stance on issues ranging from transmission glitches to hydraulic woes and from engine setbacks to electrical hiccups. The strategic maintenance planning of these prominent tractors involves not only early detection and resolution of such issues but also consistent upkeep and care.

By embracing a preventative approach to maintenance, owners can enhance tractor longevity and ensure optimal functionality. The process encompasses timely interventions such as adjusting valve timing, refilling essential fluids like coolant and hydraulic oils, and overhauling worn components. This attentive care reduces the risk of disruptions and contributes to the long-term reliability of the machinery.

In summary, the effective and efficient management of John Deere 7600 challenges is pivotal. Farmers and operators are encouraged to integrate strategic maintenance planning into their routines to bolster the tractor’s effectiveness in agricultural engagements. After all, a well-maintained tractor is synonymous with sustained productivity, and such diligent practices are the cornerstone of farming success as they prominently bolster agricultural equipment efficiency.

FAQ

What are common symptoms of John Deere 7600 clutch issues?

Clutch issues in John Deere 7600 tractors often manifest as a lacking engagement in ranges B, C, and D, leading to no traction or abrupt movement when changing gears. Symptoms might include a difficult-to-engage clutch pedal, unusual noises, or a tractor that won’t move despite being in gear.

How complicated is a John Deere 7600 transmission repair?

Transmission repairs on a John Deere 7600 can be quite complex, particularly if it involves clutch pack replacements or dealing with powerquad issues. The difficulty in achieving smooth gear shifting or addressing hard starting engines often necessitates extensive disassembly and the expertise of a trained technician.

What could cause steering problems in a John Deere 7600?

Steering issues in the 7600 series may arise from a variety of causes, including low hydraulic fluid levels, defects in the steering cylinder, or a failing steering pump. A steering wheel that turns without resistance is a common symptom of these problems.

How does one troubleshoot hydraulic system issues in the John Deere 7600?

Troubleshooting hydraulic problems in a John Deere 7600 involves checking for the correct hydraulic oil levels, inspecting the hydraulic pump and steering cylinders for failures, and ensuring the differential lock and brakes are functioning properly. Signs of malfunction might include hard steering, system leaks, or an inoperative differential lock.

What could be the reason behind engine starting difficulties in a John Deere 7600?

Difficulties in starting the engine of a John Deere 7600 tractor could stem from a variety of factors such as restricted fuel lines, clogged air filters, contaminated fuel, sluggish starter motor operation, or air in the fuel system. Each issue requires a specific approach, ranging from cleaning components to replacing defective parts.

What are common ignition system failures in the John Deere 7600?

Ignition system failures in the John Deere 7600 can be traced back to problems such as faulty spark plugs, improper valve timing, and cylinder bore wear that need precise adjustments or repairs.

How can I diagnose and fix overheating issues in my John Deere 7600?

Overheating in the John Deere 7600 tractor can be diagnosed by inspecting the cooling system for low coolant levels, blockages in the radiator, or potential engine overload. Solutions may include refilling coolant, cleaning the radiator, or evaluating the engine for worn-out components such as piston rings.

What maintenance strategies can ensure the longevity of my John Deere 7600?

To maintain the longevity of your John Deere 7600 tractor, adopt a strategic maintenance plan that includes regular inspections, prompt repairs, and adherence to service intervals. Focus on critical areas like the engine, transmission, hydraulic systems, and electrical components to ensure all parts are functioning optimally and to prevent unexpected breakdowns.

Leave a Reply