Are you a proud owner of a John Deere 750 4WD tractor? While this powerful machine is known for its rugged performance, it’s not immune to common tractor problems. In this article, we will delve into the JD 750 issues that you may encounter and provide valuable insights and potential fixes to keep your tractor running smoothly.

From hydraulic problems to transmission issues and clutch malfunctions, the John Deere 750 can present a range of challenges. But fear not, our experienced team has compiled a comprehensive guide to help you troubleshoot and resolve these problems effectively.

Let’s dive into the nitty-gritty of common John Deere 750 problems and equip you with the knowledge needed to overcome them. Whether it’s addressing hydraulic-related issues, resolving transmission problems, troubleshooting clutch malfunctions, or tackling other potential concerns, we’ve got you covered.

Stay tuned as we explore each problem in detail and provide expert tips and guidance for fixing your John Deere 750 tractor. With our insights, you’ll be able to approach maintenance and repairs with confidence, ensuring that your JD 750 remains a reliable workhorse for years to come.

Common Hydraulic Problems

Hydraulic issues are a common problem with the John Deere 750 tractor. These problems can manifest in various ways, causing inconvenience and affecting the overall performance of the machine. Let’s take a closer look at some of the most common hydraulic problems and their potential solutions.

Broken Tach Cable:

A broken tach cable is one hydraulic issue that can impact the accuracy of the hour meter on the John Deere 750. This can make it difficult to track the tractor’s usage and schedule maintenance accordingly. To resolve this problem, the broken tach cable should be replaced with a new one to ensure accurate hour meter readings.

Difficulty Lifting the Front of the Tractor:

Another hydraulic problem that owners may encounter with the John Deere 750 is difficulty in lifting the front of the tractor. This issue is often caused by a problem in the hydraulic valve. The valve may need to be inspected and repaired or replaced if necessary to restore proper lifting capacity.

Steering Gearbox Play and Worn Tie Rod Ends:

Owners may also experience steering instability due to steering gearbox play and worn tie rod ends. This can make it challenging to maneuver the tractor efficiently and safely. To address this issue, the steering gearbox and tie rod ends should be inspected and replaced if worn or damaged.

Hanging Brakes:

Hanging brakes can be another hydraulic problem faced by John Deere 750 owners. This occurs when the brakes do not release fully, causing the tractor to drag or become difficult to operate. Freeing up the hanging brakes may require inspecting and adjusting the brake components or replacing worn parts as necessary.

Engine Revving Up and Down:

Some owners have reported difficulties in shutting off the John Deere 750 tractor, with the engine revving up and down on its own. This issue may indicate problems with the injection pump, which regulates the fuel supply to the engine. Inspecting and potentially replacing the injection pump can help resolve this problem.

Summary:

As illustrated, the John Deere 750 can face various hydraulic problems, including a broken tach cable, difficulty lifting the front of the tractor, steering instability, hanging brakes, and engine revving issues. While some problems can be addressed with basic troubleshooting and repairs, complex issues may require professional assistance. Regular maintenance and inspection of hydraulic components can help prevent these problems and ensure the optimal performance of the John Deere 750 tractor.

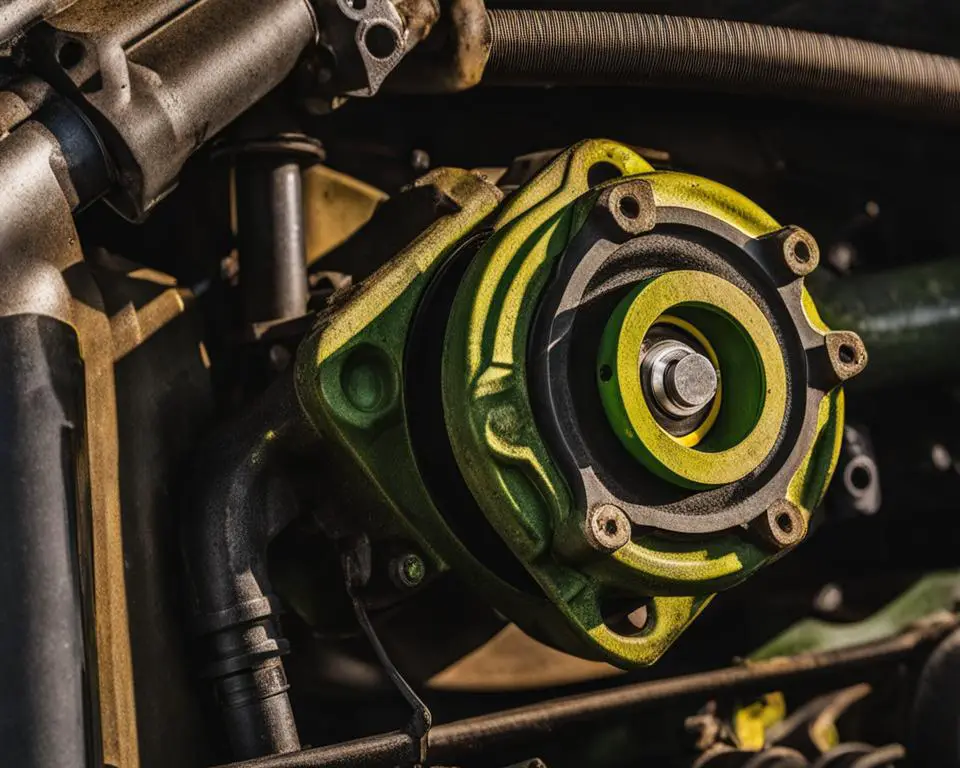

Potential Transmission Issues

When it comes to the John Deere 750 tractor, owners may encounter transmission problems that can affect the overall performance. Some common issues reported by owners include gears not engaging properly, especially at high speeds, resulting in slow or no movement. To address these problems, several steps can be taken to ensure a smooth transmission system.

First and foremost, it is crucial to inspect the driveshaft that connects the engine to the transmission. This component plays a significant role in transferring power and torque. Any misalignment or improper connection can lead to issues with gear engagement and overall performance. By conducting a thorough inspection and ensuring the driveshaft is properly connected, owners can eliminate this potential problem.

However, transmission issues are not always limited to mechanical components. Problems with the clutch can also contribute to gears not engaging and slow movement. If the clutch is worn or incorrectly adjusted, it may slip, resulting in poor performance and difficulty in maintaining speed. Therefore, it is essential to regularly check the clutch system and make any necessary adjustments or replacements to ensure smooth gear engagement and optimal transmission performance.

By addressing potential transmission issues and performing routine maintenance, owners can enhance the overall performance and longevity of their John Deere 750 tractor.

Common Transmission Problems

| Problem | Possible Cause | Solution |

|---|---|---|

| Gears not engaging | Driveshaft misalignment | Inspect and properly connect the driveshaft |

| Slow movement | Clutch wear or incorrect adjustment | Check and adjust or replace the clutch |

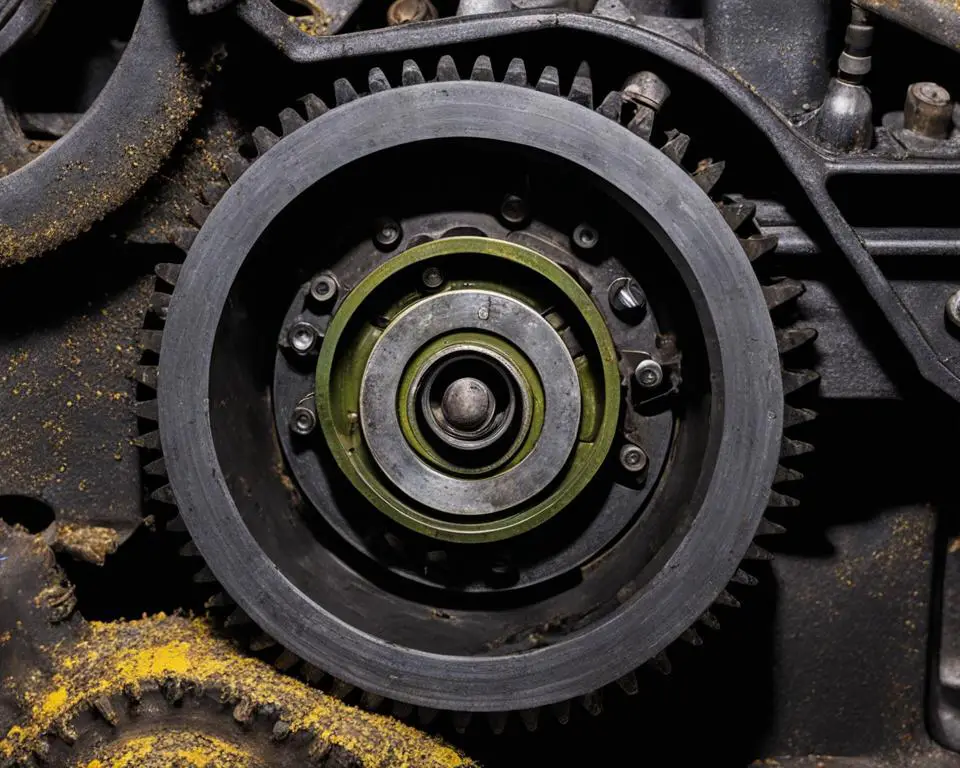

Troubleshooting the Clutch

The clutch is a critical component of the John Deere 750 tractor, responsible for transmitting power from the engine to the transmission. However, like any mechanical part, the clutch can encounter problems over time, leading to issues such as a slipping clutch or difficulty in engaging gears. In this section, we will explore troubleshooting steps to address common clutch problems encountered by John Deere 750 owners.

Identifying Clutch Problems

Before attempting any clutch adjustments or repairs, it is essential to diagnose the specific problem. Some common signs of clutch issues in the John Deere 750 include:

- Clutch slipping during operation

- Difficulty in engaging gears

- Loss of power or speed

- Failure to disengage when the clutch pedal is depressed

If you experience any of these symptoms, it is likely that your John Deere 750 tractor is facing clutch-related problems.

Adjusting the Clutch

One potential fix for clutch-related issues is adjusting the clutch pedal to ensure proper free travel. Adjusting the clutch pedal allows for better engagement and disengagement of the clutch, improving its overall performance.

To adjust the clutch pedal on the John Deere 750, follow these steps:

- Locate the clutch pedal adjustment nuts on the clutch pedal assembly.

- Loosen the nuts to create some slack in the clutch pedal linkage.

- Turn the adjustment sleeve to achieve the desired 1 inch of free travel for the clutch pedal.

- Tighten the adjustment nuts to secure the desired clutch adjustment.

By adjusting the clutch pedal to ensure proper free travel, you can improve the clutch’s engagement and disengagement, addressing issues such as slipping or difficulty in engaging gears.

Replacing the Clutch

If adjusting the clutch pedal does not resolve the problem, it may be necessary to replace the clutch entirely. Clutch replacement is a more involved process that may require specialized knowledge and professional assistance, especially for those without prior experience in tractor repairs.

If you decide to replace the clutch in your John Deere 750, it is recommended to consult the tractor’s service manual or seek the help of a qualified tractor mechanic or a John Deere dealership.

Remember, proper clutch maintenance and regular adjustments can extend the life of the clutch and ensure the smooth operation of your John Deere 750 tractor.

| Common Clutch Problems | Possible Solutions |

|---|---|

| Clutch slipping during operation | Adjust the clutch pedal for proper free travel. If the problem persists, consider replacing the clutch. |

| Difficulty in engaging gears | Ensure the clutch pedal is adjusted correctly. If the issue continues, inspect the clutch linkage and consider clutch replacement if necessary. |

| Loss of power or speed | Check the clutch for proper engagement and adjust the clutch pedal if needed. If the problem persists, consult a professional mechanic. |

| Failure to disengage when the clutch pedal is depressed | Inspect the clutch linkage and adjust the clutch pedal for proper free travel. If the clutch continues to fail disengage, seek professional assistance. |

Maintaining the Transmission

Proper maintenance of the transmission is crucial to ensure the smooth operation of the John Deere 750 tractor. Neglecting transmission maintenance can lead to a myriad of problems, including reduced performance and potential damage to the transmission system. By following a regular maintenance routine, owners can prevent costly repairs and keep their tractor operating at its best.

Regular Transmission Fluid Filter Replacement

One essential maintenance task is regularly replacing the transmission fluid filter. The transmission fluid filter plays a critical role in removing contaminants and debris from the fluid, preventing them from circulating through the transmission system and causing damage. Over time, the filter can become clogged, reducing its effectiveness and potentially leading to transmission issues.

It is recommended to refer to the tractor’s owner manual for the manufacturer’s recommended interval for filter replacement. Typically, this interval ranges from every 100 to 200 operating hours or annually, depending on usage and operating conditions. Regularly inspecting the filter for signs of dirt, debris, or clogging is also recommended and should be done more frequently if the tractor operates in dusty or harsh environments.

Transmission Fluid Change

In addition to filter replacement, regular transmission fluid changes are crucial to maintain optimal performance. Over time, transmission fluid can become contaminated or break down, reducing its ability to lubricate and protect the transmission components. Regular fluid changes help to remove any contaminants and ensure that the transmission system is properly lubricated.

The manufacturer’s recommendations for the transmission fluid change interval can vary, so it is essential to consult the tractor’s owner manual for specific guidelines. However, a general rule of thumb is to change the transmission fluid every 500 to 1,000 hours of operation or every two to three years. Prior to draining the old fluid, it is important to warm the tractor up to operating temperature to ensure thorough drainage.

When performing a transmission fluid change, it is crucial to use the manufacturer-recommended fluid type and ensure that the proper amount is added. Using the wrong fluid or not adding enough fluid can lead to poor transmission performance and potential damage.

Professional Assistance

While basic transmission maintenance tasks can often be performed by tractor owners, it is important to recognize when professional assistance is needed. If you are unsure about performing transmission maintenance or if you encounter any issues during the maintenance process, it is advisable to consult a qualified tractor mechanic or seek assistance from a John Deere dealership. They have the expertise and experience to diagnose potential problems, perform complex maintenance procedures, and ensure that your transmission is in optimal condition.

| Transmission Maintenance Checklist |

|---|

| Regularly replace the transmission fluid filter as per manufacturer recommendations. |

| Inspect the filter for signs of dirt, debris, or clogging more frequently in dusty or harsh operating conditions. |

| Follow the manufacturer’s guidelines for transmission fluid change intervals. |

| Warm the tractor up to operating temperature before draining the old transmission fluid. |

| Use the manufacturer-recommended transmission fluid type and ensure the proper amount is added. |

| Seek professional assistance if unsure or encounter any issues during maintenance. |

Other Potential Problems

In addition to the hydraulic and transmission issues, there are a few other problems that John Deere 750 owners may face. One of these problems is seed boot plugging, which has been reported by some owners, particularly on the back rows of the drill. This issue can impact the even distribution of seeds and hinder planting efficiency. To address this problem, it is recommended to inspect and replace any worn seed boots and disks, ensuring smooth and uninterrupted seed flow.

Furthermore, steering issues can arise in the John Deere 750 tractor, affecting maneuverability and stability. Side draft wearing pivots and excessive play in the openers’ arms can cause steering problems, making it difficult to maintain control of the tractor. It is essential to regularly inspect these components and replace any worn or damaged parts to ensure safe and efficient operation.

Attend to these other potential problems promptly to maintain the optimal performance of your John Deere 750 tractor.

| Other Potential Problems | Suggested Solutions |

|---|---|

| Seed boot plugging on back rows of the drill | Inspect and replace worn seed boots and disks |

| Steering issues such as side draft wearing pivots and excessive play in the openers’ arms | Regularly inspect and replace worn or damaged components |

Seeking Professional Assistance

While some issues with the John Deere 750 can be resolved with DIY solutions, it is important to acknowledge that certain problems may require professional assistance. In cases where the root cause of the problem is not apparent, or if the issue persists after attempting basic troubleshooting steps, it is recommended to consult a qualified tractor mechanic or a John Deere dealership for diagnosis and repair.

Conclusion

The John Deere 750 tractor, while being a reliable workhorse, can experience various problems over time. However, owners can take proactive steps to address and resolve these issues by understanding common problems such as hydraulic issues, transmission problems, and clutch malfunctions.

A key aspect of preventing these problems is regular maintenance. By replacing the transmission fluid filter and adhering to the manufacturer’s guidelines for maintenance, owners can minimize potential issues and ensure the smooth operation of their John Deere 750 tractor.

However, in cases where problems persist or require specialized knowledge, it is advisable to seek professional assistance. Consulting a qualified tractor mechanic or visiting a John Deere dealership can provide expert diagnosis and repair services, ensuring that any issues with the tractor are effectively resolved.

FAQ

What are some common hydraulic problems with the John Deere 750?

Common hydraulic problems with the John Deere 750 include broken tach cables, difficulty lifting the front of the tractor, steering gearbox play, worn tie rod ends, hanging brakes, and engine revving up and down.

What are potential transmission issues with the John Deere 750?

Potential transmission issues with the John Deere 750 include gears not engaging properly, particularly in high speed, resulting in slow movement or no movement.

How can I troubleshoot the clutch on my John Deere 750?

To troubleshoot the clutch on the John Deere 750, you can try adjusting the clutch pedal to ensure proper free travel. If that doesn’t resolve the issue, it may be necessary to replace the clutch.

What maintenance tasks should I perform to maintain the transmission of my John Deere 750?

Regularly replacing the transmission fluid filter and following the manufacturer’s recommendations for transmission fluid changes are important maintenance tasks to ensure optimal performance and longevity of the John Deere 750.

What are some other potential problems I may face with my John Deere 750?

Some other potential problems with the John Deere 750 include seed boot plugging in certain conditions, particularly on the back rows of the drill, and steering issues such as side draft wearing pivots and excessive play in the openers’ arms.

When should I seek professional assistance for my John Deere 750?

If basic troubleshooting steps do not resolve the problem or if the root cause is not apparent, it is recommended to consult a qualified tractor mechanic or a John Deere dealership for diagnosis and repair.

Leave a Reply