When it comes to modern farming efficiency, the John Deere 5100E stands out as a stalwart companion. This model is praised for its robustness and stamina in the field – an absolute necessity for farmers who demand reliability from their equipment. However, even the most dependable utility tractors may face their share of challenges. In this exploration, we delve into the typical John Deere 5100E issues, providing insights into common tractor problems. From tractor maintenance best practices to troubleshooting John Deere

tractors, and overcoming utility tractor difficulties, you’ll learn to keep your 5100E running like clockwork.Key Takeaways

- Diligent maintenance is key to resolving common tractor problems.

- Understanding specific John Deere 5100E issues can prevent extended downtime.

- Regular maintenance schedules bolster tractor maintenance effectiveness.

- Effective troubleshooting John Deere tractors demands an acute awareness of operational nuances.

- Proactively addressing utility tractor difficulties enhances long-term performance.

The John Deere 5100E Tractor: A Study in Durability

For many farmers, the benchmark for measuring success in equipment acquisition lies in tractor durability and equipment reliability. The John Deere 5100E tractor emerges as a pinnacle of resilience in the demanding world of agriculture. Known for its John Deere longevity, this workhorse boasts the ability to endure up to 10,000 hours of labor. This impressive lifespan owes itself to a combination of engineered fortitude and meticulous adherence to maintenance protocols.

While it’s celebrated for its robust construction, even the most high-performance utility tractors may exhibit signs of wear. Timely attention to routine services and operative care is paramount in circumventing potential issues that could impede efficiency. Such a disciplined approach to maintenance is not merely a suggestion—it’s a necessary engagement to retain the hallmark steadfastness associated with John Deere machines.

| Lifespan Marker | John Deere 5100E | Average Tractor |

|---|---|---|

| Operational Hours | Up to 10,000 hours | ~4,000 hours |

| Maintenance Schedule Adherence | Essential for longevity | Varies by model |

| Built for Workload | Yes, within recommended limits | Subject to individual specs |

| Typical Maintenance Concerns | Engine, Transmission, Steering | Varies by use and model |

The resilience of a tractor is a reflection of its maker’s commitment to quality. Indeed, the 5100E stands as a testament to John Deere’s mission to equip farmers with reliable and efficient machinery. However, as with any piece of complex equipment, vigilance in observation and upkeep is indispensable. Acknowledging the signals of distress, whether they be from the engine, transmission, or steering components, allows for interventions that preserve the tractor’s condition and safeguard its operational competence.

- Engine Maintenance: Regular check-ups and timely part replacements to prevent bogging and power loss.

- Transmission Care: Adequate servicing and use within workload limits to avoid slippage and gear trouble.

- Steering System Checks: Frequent inspections and maintenance to ensure minimal resistance and correct alignment.

In conclusion, the 5100E’s defining characteristic is its endurance. This durability, fostered by scrupulous maintenance and mindful operation, aligns with the demands of modern farming, where every hour of uptime translates to productivity on the field. Thus, it’s undeniably clear that when it comes to high-performance utility tractors, the John Deere 5100E exemplifies both a robust build and a legacy of endurance.

Unraveling John Deere 5100E Problems: Engine Troubles and Solutions

John Deere’s 5100E tractor is recognized for its robust engine performance and durability in diverse farming operations. However, like all complex machinery, it is susceptible to occasional engine troubles that may impede its functionality. Addressing these issues promptly through comprehensive engine diagnostics cannot only resolve immediate concerns but also help in preventing future disruptions to your agricultural workflow.

Effective problem-solving begins with identifying and understanding the typical problems that can arise. Once the issue has been pinpointed, engine repair techniques can be applied to address the symptoms, resulting in a tractor that continues to perform at its best.

Challenges with Engine Bogging

One of the more common issues encountered by John Deere 5100E operators is engine bogging. This condition, which affects the tractor’s ability to operate efficiently, can be linked to a myriad of causes such as clogged fuel filters or the presence of air within the fuel system. Other potential culprits include malfunctioning injectors or issues with the fuel pump. These factors can severely impact engine performance, making troubleshooting engine bogging a critical skill for any operator or technician.

Defining Symptoms of Engine Issues

Noticing the early signs of engine issues can be pivotal in resolving power loss and averting more significant engine damage. Symptoms often manifest as poor acceleration, discernible power loss at higher speeds, unusual noises from the engine compartment, and an increase in black exhaust smoke. Appreciating these nuances is essential in diagnosing engine complications with accuracy and initiating a timely response.

Steps for Remedying Engine Problems

The path to fixing throttle issues begins with a methodical approach to diagnostics and repair. Initiating a thorough inspection and engine diagnostics can reveal whether obstructions are present, followed by testing cylinder pressure to assess overall engine health. If the fuel system is suspected of having air, the appropriate resolution involves bleeding the system with precision, ensuring all excess air is expelled.

Repair protocols often require the replacement of the fuel filter if clogs are detected, cleaning or swapping out injectors if they are found to be at fault, and repairing or replacing the fuel pump as needed. Utilizing these strategic engine repair techniques is essential in restoring the tractor’s power and efficiency.

Ultimately, nipping engine issues in the bud through regular diagnostics and maintenance minimizes the risk of unexpected tractor downtime and maximizes productivity. It’s the proactive steps taken toward maintenance that safeguard the 5100E’s engine from prolonged issues, cementing its status as a dependable piece of farming equipment.

Steering System Struggles in the 5100E Model

Operators of John Deere’s 5100E tractor models often encounter steering resistance that signifies the need for steering system maintenance or hydraulic cylinder repair. These John Deere steering issues can drastically affect maneuverability and the overall efficiency of farming operations. Adequate and timely steering system maintenance ensures smooth operation and is essential for tractor longevity.

To diagnose steering system problems, operators must be alert to the effort required to steer at various speeds. A visual inspection of the steering components for wear and damage is an essential first step followed by the application of diagnostic tools. Among the most reliable of these tools are dial indicators that assess the play and a pressure gauge to investigate potential leaks in the hydraulic cylinders.

- Noticeable Play: Indicates worn ball joints or damaged linkages

- Fluid Leaks: Often observed around hydraulic cylinders and connectors

- Detecting Stiffness: Can indicate a need for hydraulic cylinder repair

On discovering the underlying cause of steering resistance, addressing John Deere steering issues involves replacing the compromised parts. Consistency with OEM specifications for replacement parts is crucial for maintaining the integrity of the steering system. Continuing with a systematic maintenance routine can preempt future issues and ensure smoother operation.

| Steering Issue Symptom | Potential Cause | Suggested Diagnostic Tool | Maintenance Action |

|---|---|---|---|

| Excessive Steering Wheel Resistance | Worn/Damaged Steering Components | Dial Indicator | Replace Worn Parts |

| Difficulty in Wheel Turn | Hydraulic System Leak | Pressure Gauge | Hydraulic Cylinder Repair |

| Unusual Steering Wheel Play | Loose Linkages/Ball Joints | Visual Inspection | Tighten or Replace Linkages/Joints |

Integrating routine checks of steering fluid levels, along with careful observation of steering behavior, can significantly contribute to the prevention of steering system problems. The key to maintaining efficient and reliable performance lies in recognizing the early signs of wear and promptly conducting necessary repairs and replacement. When managed effectively, the steering system of the John Deere 5100E tractor remains responsive and dependable, echoing the legacy of John Deere’s commitment to quality in agricultural machinery.

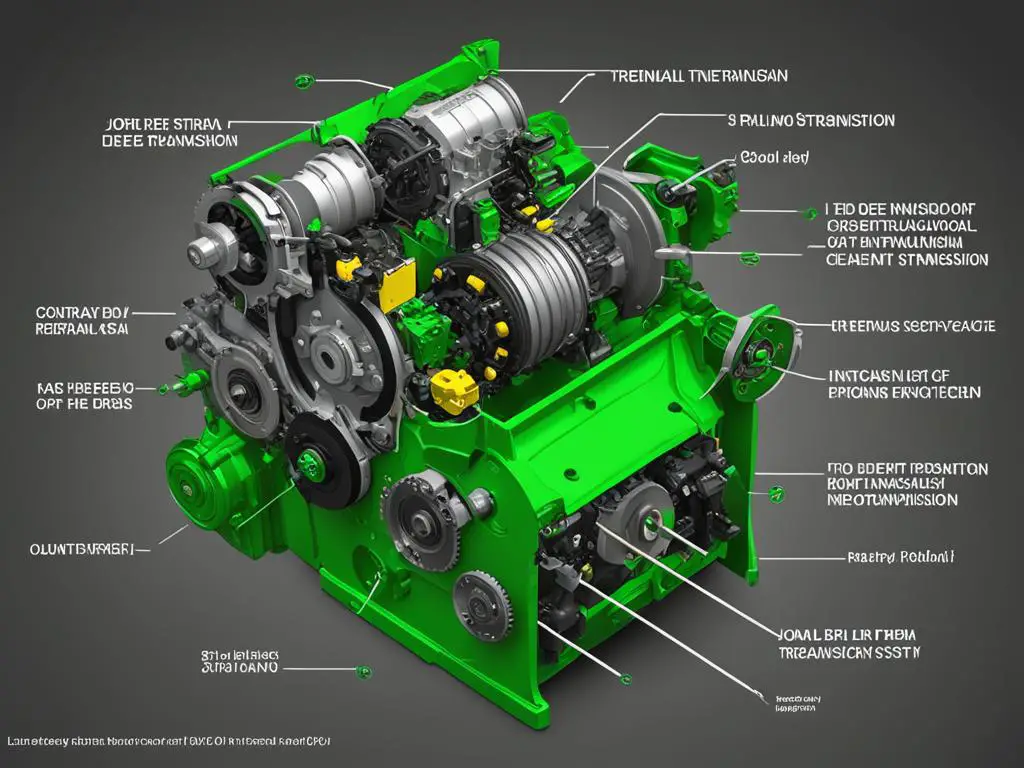

Transmission Tribulations: Identification and Repair

Among the challenges faced by the John Deere 5100E, transmission complications stand tall, potentially affecting the tractor’s performance. Successful transmission repair requires keen observation and methodical approach to John Deere transmission troubleshooting. Significant insights into the causes and solutions of these issues come from a combination of the operator’s experiences and detailed mechanical analysis.

Recognizing Transmission Failure

Early detection of transmission failure is key to minimizing downtime and costly repairs. Operators should stay vigilant for symptoms like difficulties in gear shifting, spotting gear slippage, or hearing unusual sounds beneath the hood. In some instances, the tractor may even exhibit excessive vibrations during operation, which can stem from overloading or lack of regular servicing. These signs, often the harbingers of trouble, can quickly lead to impaired functioning if not addressed.

Diagnostic Tools and Techniques for Transmission Issues

When tackling transmission woes, using the right diagnostic tools is crucial. Tractor operators and mechanics can conduct thorough visual inspections to check for noticeable wear and tear. For a more in-depth examination, employing tools such as a hydraulic system pressure tester aids in locating internal issues that aren’t immediately apparent. Here’s where servicing tractors with accuracy and diligence plays a significant role in preserving the health of the machine.

Key Maintenance to Prevent Transmission Woes

Proactive maintenance is indispensable in warding off transmission troubles. Regular checks, including fluid level examinations and replacing of critical parts like gaskets, seals, oil filters, solenoids, and clutches, go a long way in servicing tractors effectively. Adherence to the 5100E tractor’s service schedule, upholding its resilience even when faced with heavy workloads, is not just prudent; it’s a requirement for reliable operation.

| Issues in Transmission | Common Signs and Symptoms | Preventive Measures |

|---|---|---|

| Gear Slippage | Delays in acceleration, unusual noises | Regular fluid level checks, timely clutch adjustments |

| Difficulty Shifting | Hard gear shifts, unresponsive lever | Inspection of linkages and synchro rings |

| Vibrations During Operation | Shakes or erratic movements | Balance and servicing of moving parts |

By adopting a vigilant stance on transmission repair and maintenance, owners can rest assured that their John Deere 5100E will continue to tackle the demanding tasks it’s renowned for. Understanding the nuances of John Deere transmission troubleshooting is as important as the physical repairs themselves, ensuring that the tractor operates without interruption season after season.

Start-Up Hurdles: Tackling Hard Starts in the 5100E

Hard starting issues with the John Deere 5100E can be both frustrating and time-consuming to resolve. Understanding the root causes of such difficulties is essential for quick and efficient troubleshooting. Initiating a reliable start is critical to the daily operations of farming, and as such, pinpointing the typical factors leading to start-up challenges is a crucial first step.

Common Culprits Behind Starting Difficulties

Among the wide range of potential issues, battery terminal corrosion emerges as a frequent offender when it comes to start-up problems. Corroded terminals can impede the electrical connection necessary to power the tractor’s starter motor. Furthermore, a low battery charge can leave the tractor without adequate power to ignite the engine. This is often coupled with a faulty ignition switch, which fails to signal the starter to turn the engine over, or with failing starter motor components, leading to an unsatisfactory cranking attempt.

Effective Diagnostic Approach for Start-Up Issues

Electrical troubleshooting is essential in resolving such starting issues. Listening for telltale sounds when the ignition key is turned or inspecting for visible signs of wear and corrosion can offer initial insights. Tools such as a multimeter help in assessing the electrical health of the battery and the rest of the start-up system. This diagnostic process ensures that issues are not only fixed on the spot but are less likely to reoccur, maintaining the tractor’s dependability.

Ensuring Reliability in Ignition and Electrical Systems

Addressing hard starts often involves several practical steps. If corrosion is detected on battery terminals, cleaning with the appropriate solution and tools can restore connection integrity. In more severe cases, replacing the battery or servicing solenoid contacts might be necessary. The start-up system’s broader health might also require ignition system repair or replacement of worn-out starter components. Ensuring these electrical connections are clean and secure is paramount to preventing future issues.

- Clean or replace battery terminal connections to combat corrosion

- Service or replace faulty ignition switches and solenoid contacts for improved electrical flow

- Repair or refurbish starter motor components to ensure strong cranking power

- Conduct regular electrical system checks to anticipate and prevent future start-up problems

In conclusion, a comprehensive approach towards diagnosing and correcting the starting difficulties of the John Deere 5100E ensures its readiness for work at the turn of a key. Timely resolutions, based on accurate diagnostics and effective repairs, contribute to the tractor’s reputation for robust and reliable performance, keeping productivity losses to a minimum.

Conclusion

The John Deere 5100E tractor exemplifies reliable tractor operation with an impressive track record of efficiency and endurance. However, attaining this level of reliability doesn’t happen by chance. It is the result of deliberate and proactive maintenance, which involves precise diagnostics, regular check-ups, and the use of genuine OEM parts for replacements. By embracing these practices, farmers can circumvent many of the farm equipment issues commonly associated with tractor upkeep.

From tackling engine bogging to addressing transmission abnormalities and ensuring smooth steering operations, each maintenance action contributes to the John Deere 5100E efficiency that operators have come to expect. It’s this proactive stance on upkeep that not only prevents downtime but also enhances the tractor’s longevity, solidifying its role as an invaluable asset on any farm.

Ultimately, by avoiding farm equipment issues through foresight and careful attention to tractor care, the John Deere 5100E stands as a paragon of durability and operational excellence. It is the owner’s knowledge, coupled with vigilant maintenance, that ensures the 5100E continues to serve the demanding needs of modern agriculture faithfully, day in and day out, preserving the strong customer loyalty synonymous with the John Deere brand.

FAQ

What are the most common issues with the John Deere 5100E?

Common problems include engine bogging, transmission failure, steering system resistance, and difficulties with starting the tractor.

How long can a John Deere 5100E last with proper maintenance?

With adherence to maintenance schedules, John Deere 5100E tractors can reach up to 10,000 operating hours.

What symptoms indicate engine bogging in the 5100E?

Symptoms of engine bogging can include poor acceleration, power loss, unusual engine noises, and black exhaust smoke.

How can steering wheel resistance be addressed in the 5100E model?

Addressing steering resistance may involve replacing worn components in the steering system and ensuring the hydraulic system is leak-free and properly maintained.

What diagnostic steps should be taken for transmission failure?

Transmission failure diagnostics include checking for wear and tear, using hydraulic pressure testers, and inspecting fluid levels.

What are some solutions to starting difficulties with the John Deere 5100E?

Solutions include cleaning or replacing the battery terminals, checking the battery charge, and servicing or replacing components of the starter motor.

How often should I maintain my John Deere 5100E tractor to prevent common problems?

Regular maintenance schedules vary, but it is crucial to adhere to the manufacturer’s guidelines, including routine checks and timely replacement of parts.

Can engine problems lead to reduced tractor efficiency?

Yes, unresolved engine problems can lead to reduced efficiency and performance. Regular engine diagnostics and prompt action are essential to maintain tractor efficiency.

What is the best way to prevent transmission issues in the 5100E?

Preventing transmission issues involves regular checks, keeping the hydraulic fluid at the correct level, and replacing parts like gaskets, seals, and filters as required.

Are there specific parts I should use when replacing components on my 5100E?

It is recommended to use OEM (Original Equipment Manufacturer) parts for replacements to ensure the best fit and performance.

Leave a Reply