The John Deere LT155 is a popular riding lawnmower from the early 2000s. While it is a reliable and high-quality machine, it can experience some common problems.

These problems include engine issues, hydrostatic transmission problems, fuel pump problems, steering problems, starting problems, and overall wear and tear. However, most of these problems can be easily fixed with proper maintenance and timely repairs.

In the following sections, we will discuss each of these problems in detail, providing insights into their causes and practical fixes. By understanding these common issues, LT155 owners can ensure the longevity and optimal performance of their lawnmower.

John Deere LT155 Engine Problems

The engine of the John Deere LT155 is powered by a 15 horsepower Kohler engine. While this engine is known for its reliability, there are some common problems that owners may encounter. The most frequent issues include difficulty starting the engine, sudden engine stalling, and a lack of power.

One of the primary culprits behind these engine problems is a faulty ignition coil. The ignition coil is responsible for generating the spark that ignites the fuel-air mixture in the engine, allowing it to start and run smoothly. If the ignition coil is defective, it can cause starting issues and intermittent engine stalling.

Replacing the faulty ignition coil is a relatively simple fix that can resolve these engine problems.

However, if changing the ignition coil does not solve the issue, it is recommended to take the mower to a mechanic for a complete repair. A professional technician can diagnose and address any underlying issues that may be causing the engine problems.

“I had trouble starting my John Deere LT155, and after replacing the ignition coil, it started right up without any issues. It’s essential to maintain the engine properly and address any problems promptly to ensure smooth operation.” – John, LT155 Owner

John Deere LT155 Hydrostatic Transmission Problems

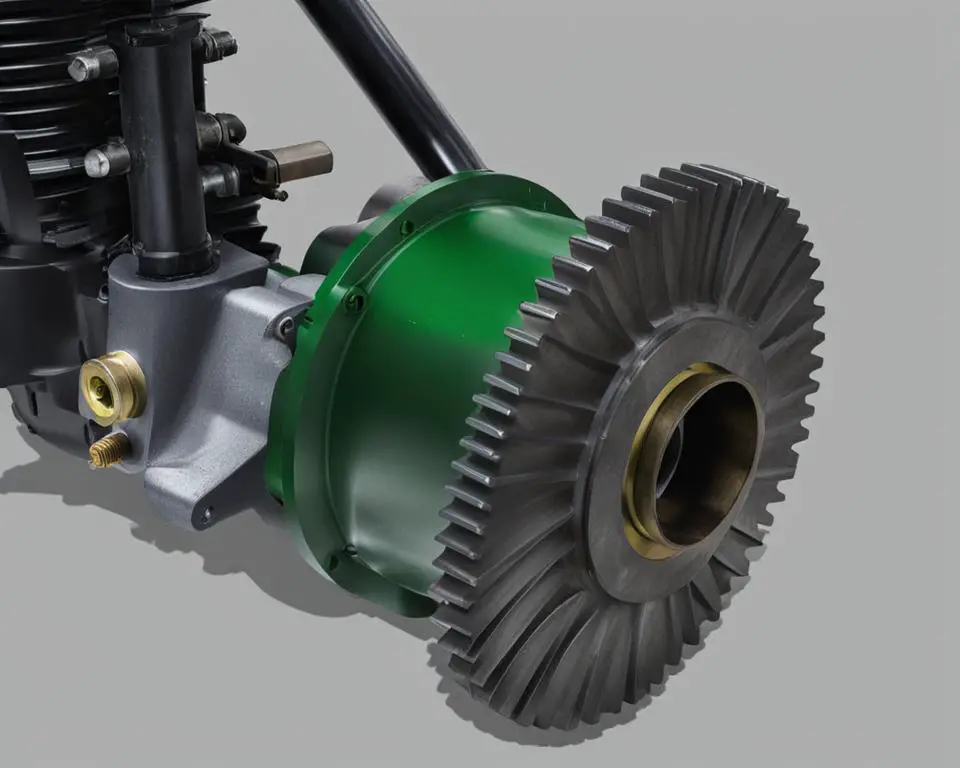

As an owner of the John Deere LT155, you may encounter various issues with its hydrostatic transmission system. The hydrostatic transmission is responsible for transferring power from the engine to the hydraulic pumps, which in turn rotate the wheels.

One common problem that users face is a lack of pressure in the transmission system, often caused by cavitation. Cavitation occurs when air bubbles form in the hydraulic fluid due to low pressure, resulting in reduced performance and potential transmission failure.

To resolve cavitation and restore proper transmission functionality, it is crucial to clean the hydraulic transmission system thoroughly.

In addition to cavitation, other transmission issues may arise, such as sluggish performance and complete failure. These problems can be caused by various factors, including worn-out components or mechanical failures.

If you experience any transmission issues that cleaning alone cannot fix, it is recommended to have your John Deere LT155 inspected and repaired by a professional technician or authorized service center. These experts have the expertise and knowledge to diagnose and address the specific transmission problem efficiently.

Common John Deere LT155 Hydrostatic Transmission Problems:

- Lack of pressure due to cavitation

- Sluggish performance

- Transmission failure

“Taking care of the hydrostatic transmission system is vital to ensure seamless operation of your John Deere LT155. Regular maintenance, including cleaning and inspection, can prevent potential issues and extend the lifespan of your mower.”

To gain a better understanding of the hydrostatic transmission system in the John Deere LT155, refer to the table below:

| Component | Description |

|---|---|

| Hydrostatic Pump | Converts mechanical power from the engine into hydraulic pressure. |

| Hydraulic Motor | Receives hydraulic pressure from the pump and converts it into mechanical power to rotate the wheels. |

| Transmission Fluid | Provides hydraulic power transmission and lubrication for the system. |

| Filters | Remove contaminants and debris from the transmission fluid to maintain optimal performance. |

Regular maintenance, including cleaning the hydraulic transmission system and immediate attention to any transmission problems, is essential to keep your John Deere LT155 running smoothly and efficiently.

John Deere LT155 Fuel Pump Problems

Fuel pump problems can be a common issue that John Deere LT155 owners may encounter. These problems can prevent the mower from running smoothly or even starting at all. Understanding the potential fuel pump issues and knowing how to address them is essential for maintaining the performance of your LT155. Some of the most common fuel pump problems include:

- Clogs caused by dirt or debris in the fuel tank

- Improper fuel flow

- Leaks in the fuel system

To resolve these fuel pump problems, there are a few steps that you can take:

- Start by checking the fuel pump connection to ensure it is secure.

- Next, clean the fuel system to remove any clogs or debris. This can involve removing the fuel tank and cleaning it thoroughly.

- If the fuel pump is damaged or faulty, it may need to be replaced. Ensure that all components are properly installed and functioning.

By addressing fuel pump problems promptly and following these steps, you can ensure that your John Deere LT155 continues to run smoothly and efficiently.

Comparison of LT155 Fuel Pump Problems and Solutions

| Fuel Pump Problems | Solutions |

|---|---|

| Clogs from dirt or debris in the tank | Clean the fuel system, remove and clean the fuel tank |

| Improper fuel flow | Check fuel pump connection, ensure proper installation, and consider replacing the fuel pump if necessary |

| Fuel system leaks | Inspect the fuel system for leaks, repair or replace any damaged components |

John Deere LT155 Steering Problems

Steering problems can be a safety concern when operating the John Deere LT155. Common steering issues include inability to turn left, being stuck in one position, and difficulties in forward or reverse movement. These problems are often caused by damage to mechanical components such as the rack, pinion gear, bearings, drive belts, and idlers. Proper inspection and repair of these components can help resolve steering issues.

To better understand the potential steering difficulties that can arise with the John Deere LT155, let’s take a closer look at some of the key mechanical components:

Rack and Pinion Gear

The rack and pinion gear system is responsible for translating the steering input to the wheels. Over time, the rack and pinion gear can experience wear and tear, leading to steering problems. Regular inspection and lubrication of this system, along with timely replacement of any worn-out components, can improve steering performance.

Bearings

Bearings play a crucial role in allowing smooth rotation of the steering components. When bearings become damaged or worn out, they can impede proper steering movement. Regular greasing and replacement of worn bearings can help maintain smooth steering operation.

Drive Belts and Idlers

The drive belts and idlers ensure that power from the engine is properly transferred to the steering system. If these components become loose or damaged, they can hinder steering functionality. Regular inspection and adjustment of the drive belts and idlers, along with timely replacement if necessary, can improve steering performance.

“Proper inspection and repair of the mechanical components can help resolve steering issues in the John Deere LT155.”

By addressing steering problems promptly and conducting regular maintenance, you can ensure safe and efficient operation of your John Deere LT155. Consult the mower’s manual or seek professional assistance if you are unsure about inspecting or repairing the steering components.

Conclusion

The John Deere LT155 is a reliable lawnmower that can provide many years of service when properly maintained. Regular maintenance is key to ensuring its longevity and optimal performance. By following a few simple steps and paying attention to the machine’s needs, owners can enjoy the benefits of a well-functioning LT155 and a beautifully manicured lawn.

One of the most important aspects of maintenance is regularly checking and cleaning the various components of the LT155. This includes inspecting the engine, transmission, fuel system, and steering mechanism for any signs of wear, damage, or debris. Addressing these issues promptly can prevent them from escalating and causing more significant problems down the line.

In addition to regular inspections, it is crucial to replace worn-out parts as needed. Over time, certain components of the LT155 may become less effective or fail completely. By replacing these parts at the first sign of trouble, owners can avoid further damage and extend the life of their lawnmower.

By incorporating these maintenance practices into their routine, John Deere LT155 owners can maximize the longevity and performance of their machine. With proper care and attention, the LT155 can provide up to 10 years of reliable service, ensuring a well-kept and beautiful lawn for years to come.

FAQ

What are some common problems with the John Deere LT155?

The common problems with the John Deere LT155 include engine issues, hydrostatic transmission problems, fuel pump problems, and steering problems.

What are some engine problems that can occur with the John Deere LT155?

Some common engine problems with the John Deere LT155 include difficulty starting, sudden engine stalling, and lack of power.

How can engine problems with the John Deere LT155 be resolved?

Engine problems with the John Deere LT155 can be resolved by replacing the faulty ignition coil or seeking professional repair if the issue persists.

What are some hydrostatic transmission problems that can occur with the John Deere LT155?

Some common hydrostatic transmission problems with the John Deere LT155 include lack of pressure, sluggish performance, and transmission failure.

How can hydrostatic transmission problems with the John Deere LT155 be resolved?

Hydrostatic transmission problems with the John Deere LT155 can be resolved by cleaning the hydraulic transmission system or seeking professional inspection and repairs.

What are some fuel pump problems that can occur with the John Deere LT155?

Some common fuel pump problems with the John Deere LT155 include clogs from dirt or debris, improper fuel flow, and leaks.

How can fuel pump problems with the John Deere LT155 be resolved?

Fuel pump problems with the John Deere LT155 can be resolved by checking the fuel pump connection, cleaning the fuel system, and replacing damaged components.

What are some steering problems that can occur with the John Deere LT155?

Some common steering problems with the John Deere LT155 include inability to turn left, being stuck in one position, and difficulties in forward or reverse movement.

How can steering problems with the John Deere LT155 be resolved?

Steering problems with the John Deere LT155 can be resolved by inspecting and repairing mechanical components such as the rack, pinion gear, bearings, drive belts, and idlers.

How long can the John Deere LT155 last with regular maintenance?

With regular maintenance, the John Deere LT155 can last up to 10 years.

What does regular maintenance for the John Deere LT155 involve?

Regular maintenance for the John Deere LT155 involves checking and cleaning components, replacing worn-out parts, and addressing any problems as soon as they arise.

Leave a Reply