Tractors are the backbone of versatile farming operations, and John Deere has a longstanding history of providing reliable machinery to support America’s agricultural needs. The John Deere 7400 in particular, is known for its sustainability in farms. Farmers have come to rely on its endurance and versatility, but as with any robust equipment, it comes with its set of challenges. Addressing common issues such as hydraulic system complexities, cutting unit deficiencies, and ensuring proper maintenance can be daunting tasks. This guide delves into the John Deere 7400 troubleshooting process, providing insightful information to handle the common 7400 tractor complications. Maintaining this piece of machinery is pivotal, and with the right attention to detail, your John Deere maintenance routines will result in seamless operation and extended service life of your valued tractor.

Key Takeaways

- Recognize the importance of proper hydraulic system management to prevent overheating.

- Understand the active and passive down pressure systems for better equipment control.

- Perform regular checks on sensor lights to streamline troubleshooting efforts.

- Maintain deck durability and enhance cutting efficiency with routine mower upkeep.

- Utilize the TechControl display for consistent cut quality and effective diagnostic monitoring.

- Embrace the eHydro system to surmount traction and terrain challenges.

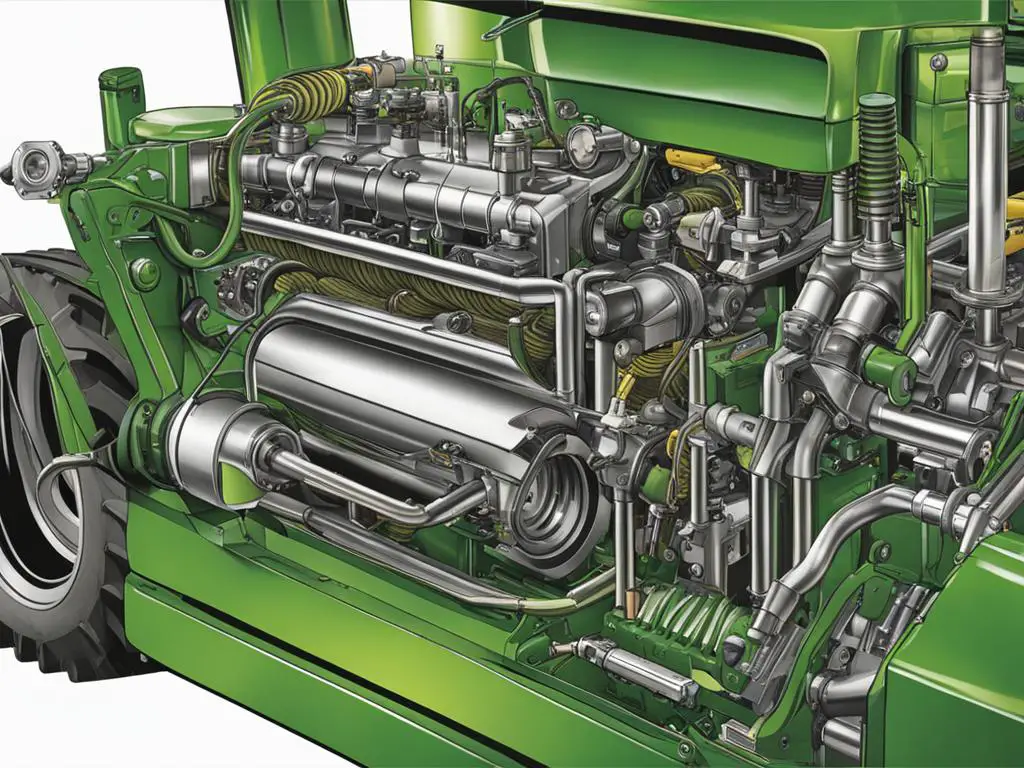

Understanding the Hydraulic System of Your John Deere 7400

Mastering the maintenance and operation of your John Deere 7400 tractor’s hydraulic system is essential for achieving peak performance and longevity. Knowledge about the differing hydraulic setups, including active and passive down pressure systems, will ensure you’re utilizing your equipment’s capabilities to the fullest while preventing common mechanical challenges.

Active vs. Passive Hydraulic Down Pressure Systems

The hydraulic down pressure system on a John Deere tractor can significantly affect how the machinery interacts with various terrains during operation. Two primary systems are commonly discussed among users: the active and passive down pressure systems. The active down pressure setup is integral for maintaining consistent force across uneven ground, necessitating that the tractor’s remote valve remains open throughout operation. Conversely, the passive system requires intervention only for raising or lowering the machinery, typically used with tractors featuring non-variable-displacement systems.

Adjusting Hydraulic Flow: Preventing Overheating

Properly adjusting hydraulic flow is crucial to prevent potential overheating issues in the John Deere hydraulic system . The tractor’s lever should be kept in the motor position to facilitate continuous operation, while precise control of the hydraulic pressure is achieved using a thumb screw on the pressure gauge. Regular fine-tuning ensures the hydraulic system runs smoothly without excess heat build-up, thereby safeguarding the longevity and optimal functionality of your John Deere 7400.

Sensor Lights and Troubleshooting Tips

Sensor indicators are designed to alert you to potential problems within your machinery. However, it’s important to differentiate between actual issues and false alarms, which can sometimes be triggered by faulty sensors. When troubleshooting sensor issues, a systematic approach to assess and rectify the underlying causes is paramount. Familiarity with the sensor systems and their alerts can guide you promptly through the troubleshooting process, preventing minor hiccups from escalating.

| Issue | Sensor Light Indication | Troubleshooting Tip |

|---|---|---|

| Hydraulic Overheating | Solid or Flashing Temperature Alert | Check flow settings and adjust as needed to reduce the strain on the system. |

| Pressure Irregularity | Pressure Gauge Fluctuation | Ensure the lever is set correctly and the pressure matches recommended levels. |

| False Sensor Trigger | Varies Based on Sensor | Inspect for sensor damage or misconnection and replace if necessary. |

With a comprehensive understanding of the John Deere hydraulic system, from maintaining active down pressure to vigilant adjusting hydraulic flow and troubleshooting sensor issues, operators can expertly navigate their 7400’s capabilities. This mastery leads not only to efficient work days in the field but also preserves the integrity of your equipment for years to come.

Design and Durability of John Deere 7400 Mower Decks

John Deere’s 7400 series sets the standard for durability and efficiency with its mower decks, engineered for peak performance even under the most challenging conditions. A hallmark of quality, these decks exemplify the blend of robust design and cutting-edge technology that place John Deere at the forefront of agricultural equipment innovation.

Stamped Rotary Decks for Consistent Performance

Equipped with meticulously crafted stamped rotary decks, the 9009A TerrainCut Rough Mower and the 7400A TerrainCut Trim and Surrounds Mower achieve consistent deck strength and reliability. This singular steel design ensures uniformity and structural integrity across the entirety of the mowing deck, presenting a foundation that’s built to last and perform.

Frame Support and Protection for Longevity

The formidable durable deck design of John Deere mower decks is further supported by a robust frame construction. Surrounding the stamped shell is a safeguarding steel framework that absorbs the brunt of environmental impacts during operation. With a focus on durability, features like front and rear roller brackets, skid plates, and reinforced edges ensure the decks withstand not only the duress of terrain but the test of time.

Optimizing Discharge for High-Quality Clipping Dispersal

John Deere has meticulously engineered their mower decks to optimize clipping dispersal. Precision-shaped for asymmetrical rear discharge, these decks seamlessly collaborate with molded chutes to streamline grass ejection. This strategic design mitigates clumping and minimizes clean-up post-mowing, which culminates in a remarkably even and superior cut quality that users can depend on season after season.

In summary, every aspect of John Deere mower decks, from the stamped rotary decks to their clipping dispersal optimization, is a testament to their unwavering commitment to quality and craftsmanship, reinforcing a legacy of resilience and excellence in agricultural machinery.

John Deere 7400 Cutting Unit Issues

As vital components of the John Deere 7400 series, the cutting units undergo rigorous use during the mowing season. Ensuring that they are properly maintained and adjusted is critical for achieving the best cutting results and prolonging the life of the machinery. Particularly, the Height-Of-Cut (HOC) adjustment system and cutting blade maintenance present two areas where operators must focus their attention to optimize performance.

Height-Of-Cut Adjustment Challenges

The John Deere cutting units are tailored with a tool-free HOC adjustment through an innovative notch system, endorsing a user-friendly approach to setting modifications. However, despite the intuitiveness of the HOC system, obtaining precise settings sometimes poses a challenge due to environmental conditions or operator error. For a consistently well-groomed turf, the height of cut on the 7400 series can range from 3/4 inches to 4 inches, and fine adjustments are pivotal to meet the exact requirements of different grass types and conditions.

John Deere’s no-tool notch adjustment system empowers operators to easily set and modify the HOC as conditions demand, advancing efficiency and adaptability in the field.

Maintaining and Sharpening Cutting Blades

Maintaining the sharpness and integrity of the cutting blades is non-negotiable for preserving the quality of cut and efficiency of the machine. Sharp blades reduce the wear on the mower and ensure a crisp, clean cut with less effort. The meticulous care for cutting blade maintenance translates to consistent cut quality, leading to healthier turf and a visually appealing landscape. Regular scrutiny and sharpening of the blades are necessary steps for managing the demands of frequent use and variable growth rates.

- Inspection: Vigilantly checking the blades for nicks, wear, and damage can prevent poor cut quality.

- Cleaning: Debris removal is vital for both the blade’s longevity and to safeguard the cutting unit from potential malfunctions.

- Sharpening: Employing proper techniques to sharpen and balance the blades guarantees a uniform cut and protects the mower’s engine from undue strain.

- Replacement: When blades are beyond restoration, timely replacement of worn or damaged blades is quintessential to maintain top-notch mowing performance.

In essence, mastering the Height-Of-Cut adjustments and ensuring meticulous cutting blade maintenance are the backbone of leveraging the full potential of John Deere cutting units within the 7400 series and cannot be overstated in their contribution to operational excellence.

Maximizing Mower Uptime with TechControl Display

To ensure peak mower performance and uptime, the integration of John Deere’s TechControl display is pivotal. It does more than streamline operations—it’s a command center that allows operators to lock in the ideal settings for efficiency and precision, crucial for maximized productivity on the course.

Understanding Operator Warning Notifications

The TechControl display goes beyond basic functionality by providing critical operator notifications. These alerts serve as the first line of defense against potential issues that could otherwise lead to downtime. By informing operators of any immediate concerns such as hydraulic over temperature or battery voltage changes, immediate action can be taken to address problems and keep the mower running smoothly.

LoadMatch: Keeping Cut Quality Consistent

Undoubtedly, cut quality is of paramount importance to any mowing operation. The TechControl’s advanced LoadMatch speed control automatically adjusts the mower’s speed in real-time, ensuring that the power delivered to the cutting units is consistent—maintaining a uniform quality of cut even in challenging conditions. This feature both enhances overall turf aesthetics and helps protect the mower from unnecessary wear.

Importance of Regular Maintenance and Service Alerts

Regular maintenance is essential for the longevity and performance of any piece of heavy equipment. With John Deere’s integrated service alerts, managing maintenance schedules becomes less burdensome. The system reminds operators of the optimal times to service hydraulic and engine oils, contributing to operational efficiency and reliability. Leveraging these John Deere service alerts ensures that the 7400 series mowers run optimally, reducing variability in operator performance and contributing to more consistent results across the board.

Hydrostatic Drive and Traction Challenges in John Deere 7400

The innovative eHydro traction system is a hallmark of the John Deere 7400, designed to offer exceptional control and agility across diverse terrains. Yet, the complexities of the advanced system present unique operational tests, not least of which are the hydrostatic drive challenges and John Deere traction issues. These challenges highlight the need for a more in-depth understanding of the 7400’s traction capabilities and limitations.

Evaluating the eHydro Traction System

The tractability of the eHydro system emerges from its state-of-the-art hydrostatic pump and wheel motors, resulting in a substantial 35% increase in pump flow and a 17% enhancement in motor displacement compared to previous models. This considerable enhancement aims to bolster the 7400’s hill-climbing prowess, tackling the taxing conditions presented by rigorous mowing and agricultural tasks. Despite these improvements, operators still report encountering setbacks when navigating steep or challenging landscapes.

Dealing with Traction and Hill-Climbing Difficulties

Managing the hydrostatic drive in the face of demanding topography entails not just an understanding of the system’s capabilities, but also practical strategies to counter traction issues. Farmers and groundskeepers must take into account factors like weight distribution, tire integrity, and surface conditions to optimize the John Deere 7400’s traction dynamically. Problem-solving in this manner enables the exploitation of the vehicle’s full potential, strengthening stability and performance across operations.

Furthermore, to alleviate operator fatigue over prolonged periods, the eHydro system has reduced pedal effort. This ergonomic enhancement, however, must align with the system’s aptitude for maintaining dependable drive control in instances of persistent inclines or uneven terrain—a crucial factor for sustained productivity.

Recognizing the interplay between the eHydro system’s innovative elements and their real-world application is essential. The system’s design, which decreases the number of parts and necessary adjustments, theoretically reduces maintenance demands and reinforces the tractor’s reliability. In practice, though, efficacy is gauged through consistent performance across all terrain profiles.

Ultimately, the eHydro traction system is a significant step in advancing the John Deere 7400’s operational range. While hydrostatic drive challenges and John Deere traction issues may arise, informed management and operational adjustments help ensure that these hurdles do not undermine the machine’s overall capacity for tackling agricultural endeavors.

Conclusion

Embarking on the journey of John Deere 7400 maintenance reveals the importance of nuanced attention to hydraulic systems, meticulous care of cutting units, and astute employment of innovative features like the TechControl display. These measures are not merely routine upkeep but are pivotal steps in enhancing 7400 performance. Success in these areas ensures operational precision and reliability that are synonymous with the John Deere brand.

The course of resolving common 7400 issues demands adherence to recommended practices, such as precise Height-Of-Cut (HOC) adjustments and a disciplined blade maintenance schedule. This diligence ensures that every cut made is of the highest quality, and the terrain masterfully managed, regardless of its rigor. Furthermore, navigating the eHydro system’s capabilities provides an edge when facing diverse topographical challenges, allowing for confident operation in varying conditions.

In the field of modern agriculture, consistent hydraulic overheating problems underscore the necessity of leveraging support resources. Consulting John Deere’s operating manuals and information sheets is more than practical—it’s a strategy that arms operators with the tools to take proactive control over potential setbacks. Building a comprehensive understanding of the 7400’s advanced systems enacts a defensive line against downtime, ensuring your equipment’s dedicated service to the demands of today’s agricultural landscape. As farmers integrate this knowledge, they can effectively transform routine maintenance into a triumph of machinery optimization, showcasing the true potential of their John Deere 7400.

FAQ

What are some common John Deere 7400 troubleshooting tips?

Common troubleshooting tips for John Deere 7400 problems include checking and adjusting the hydraulic flow to prevent overheating, inspecting sensor lights for false triggers, and consulting the operators’ manual for guidance. Keeping the cutting blades sharp and well-maintained is also vital for optimal performance.

How do the active and passive down pressure systems differ in the John Deere 7400?

In the John Deere 7400, the active down pressure system requires the remote valve to be held open during operation, whereas the passive down pressure system requires the remote valve to be open only for raising and lowering the implement. Correct flow rate adjustments ensure efficient operation.

What steps can be taken to prevent overheating in the hydraulic system of a John Deere 7400?

To prevent overheating, ensure the hydraulic flow is correctly adjusted by keeping the lever in the motor position and the thumb screw on the pressure gauge at the right setting. Regularly check the system to avoid excessive heat buildup.

How can I troubleshoot sensor issues on my John Deere 7400?

For troubleshooting sensor issues on the John Deere 7400, first verify the accuracy of the sensor readings and consult your operator’s manual. If problems persist, consider seeking professional technical support or replacement of faulty sensors.

What makes John Deere mower decks durable and efficient for clipping dispersal?

John Deere mower decks are designed for durability with stamped rotary decks from a single steel piece and additional steel stock welded at the edge for strength. The asymmetric rear discharge design with a moulded chute ensures efficient clipping dispersal and a clean cut.

How do you ensure consistent performance from John Deere stamped rotary decks?

To ensure consistent performance, John Deere stamped rotary decks feature a one-piece steel construction for strength, protective frames for longevity, and a rear discharge design that optimizes grass clipping dispersal for a uniform cut.

What challenges are associated with the John Deere 7400’s Height-Of-Cut adjustment and how can they be overcome?

The John Deere 7400’s Height-Of-Cut (HOC) adjustments are made tool-free with a notch system, but achieving precise settings can be tricky. It’s important to frequently check and adjust the HOC to maintain the desired quality of cut, especially during periods of rapid grass growth.

What’s the proper way to maintain and sharpen cutting blades on a John Deere 7400?

Maintaining and sharpening cutting blades involve selecting the correct blades for the grass type, ensuring they are sharp, and making regular adjustments. Always follow the recommended maintenance schedule provided by John Deere to maintain optimal mower performance.

How does the TechControl Display enhance John Deere 7400 mower uptime?

The TechControl Display locks in operational settings, streamlines adjustments for mowing speeds, and provides diagnostic notifications like hydraulic over-temperature, engine pressure, and battery voltage alerts, thereby helping to maximize mower uptime.

What is the LoadMatch feature and how does it improve John Deere 7400’s cut quality?

The LoadMatch feature on the TechControl Display compensates machine speed automatically to maintain power to the cutting units, which helps maintain consistent cut quality regardless of varying load conditions.

Why is regular maintenance and attention to service alerts important for the John Deere 7400?

Regular maintenance and heeding service alerts are important for ensuring the longevity and optimal functioning of the John Deere 7400. Attention to these reminders helps to prevent unexpected downtimes and maintains the tractor and mowing units in prime condition.

How does the eHydro system benefit John Deere 7400’s traction capabilities?

The eHydro system provides the John Deere 7400 with increased traction pump flow and wheel motor displacement, aiming to enhance hill-climbing abilities and overall traction. It simplifies the drive system, which can lead to reduced maintenance needs and improved stability.

What solutions are available for handling traction and hill-climbing difficulties with a John Deere 7400?

To handle traction and hill-climbing difficulties, assess and maximize the use of the eHydro system’s design, maintain proper tire pressure and tread, and ensure the machine’s weight is distributed correctly for better stability on challenging terrains.

Last updated on September 7, 2025