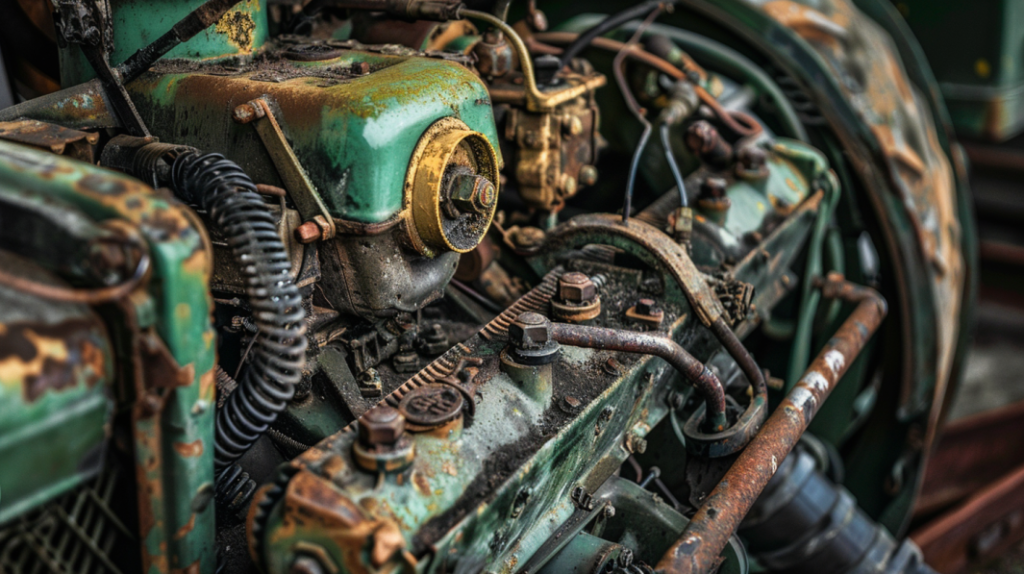

If you’ve ever faced issues with your John Deere 3010, you know how frustrating they can be. From hydraulic leaks to engine overheating, these problems can disrupt your work and cause downtime. But what if there were simple fixes that could get your tractor back in action quickly? Discover practical solutions to common John Deere 3010 problems that might just save you time and headaches.

Key Takeaways

- Hydraulic system failures from leaks or contamination require prompt repair.

- Engine overheating may stem from low coolant levels or radiator issues.

- Transmission problems like slipping gears need attention for smooth operation.

- Regularly inspect and replace hydraulic filters to maintain system efficiency.

- Monitor engine temperature gauge for signs of overheating and address promptly.

Mechanical Problems

If you’re experiencing mechanical issues with your John Deere 3010, common problems may include hydraulic system failures, engine overheating, and transmission issues.

When it comes to hydraulic system failures, check for leaks in the hoses or connectors. Verify the hydraulic fluid is at the correct level and not contaminated. Regularly inspect and replace hydraulic filters to prevent clogs that could impede performance.

For engine overheating problems, start by checking the coolant level and quality. Examine the radiator for any debris blockage and make sure the cooling fan is functioning correctly. Regularly clean the radiator to prevent overheating caused by dirt buildup. Additionally, monitor the engine temperature gauge to catch any early signs of overheating.

Concerning transmission issues, begin by checking the transmission fluid level and quality. Inspect for any leaks in the transmission system. If you notice slipping gears or unusual noises, it could indicate a more severe problem requiring professional attention. Regular maintenance and fluid checks can help prevent transmission issues and ensure smooth operation.

Engine Troubleshooting

If your John Deere 3010 is experiencing starting issues, it’s important to diagnose potential causes such as fuel system problems or ignition issues.

To prevent overheating, verify proper coolant levels and check for any blockages in the radiator or cooling system.

If you’re facing power loss, solutions may include checking the air filter, fuel filters, and making sure proper fuel quality and flow to the engine.

Starting Issues Diagnosis

When troubleshooting starting issues on a John Deere 3010, begin by checking the ignition system for any potential problems. Inspect the spark plugs, ignition wires, distributor cap, and rotor for signs of wear or damage. Confirm that the spark plugs are properly gapped and that the ignition timing is set correctly.

If the ignition system components are in good condition, move on to testing the battery. Check the battery terminals for corrosion and make sure they’re securely connected. A weak or dead battery can cause starting issues, so testing the battery’s voltage and charging system can help pinpoint the problem.

Next, examine the fuel system. Make sure the fuel tank is filled with clean, fresh fuel and that the fuel filters aren’t clogged. Check the fuel lines for any leaks or blockages.

If the ignition, battery, and fuel systems are all functioning correctly, consider testing the starter motor and solenoid for any faults. These components are essential for initiating the engine’s cranking process.

Overheating Prevention Tips

To prevent overheating in your John Deere 3010 engine, regularly check and maintain the cooling system components for optimal performance. Start by inspecting the radiator for any debris or blockages that could hinder proper airflow. Clean the radiator fins and make sure the coolant levels are adequate. Check the radiator hoses for cracks or leaks, replacing them if necessary. Additionally, examine the water pump for any signs of wear or malfunction. Proper belt tension is vital for the water pump to function effectively.

Regularly changing the coolant according to the manufacturer’s recommendations is essential to prevent overheating. Verify that the coolant mixture is correct for your engine to prevent freezing or boiling. Inspect the thermostat to ensure it opens and closes properly, regulating the engine temperature effectively.

Monitoring the temperature gauge while operating the tractor can help you detect any overheating issues early on. By following these maintenance tips, you can keep your John Deere 3010 engine running smoothly and prevent overheating problems.

Power Loss Solutions

Inspect the air filter and fuel system for clogs or blockages to troubleshoot power loss in your John Deere 3010 engine. Power loss can result from restricted airflow or fuel delivery issues. Start by checking the air filter for dirt and debris. A dirty filter can limit the amount of air entering the engine, affecting its performance. Replace the air filter if it appears dirty or damaged. Next, examine the fuel system for any obstructions. Clogs in the fuel lines or a dirty fuel filter can impede the flow of fuel to the engine, leading to power loss. Confirm that the fuel lines are clear, and replace the fuel filter if necessary.

To further diagnose and address power loss in your John Deere 3010, refer to the table below for additional troubleshooting steps:

| Issue | Possible Cause | Solution |

|---|---|---|

| Dirty Air Filter | Restricted airflow | Replace air filter |

| Clogged Fuel Filter | Fuel delivery issues | Replace fuel filter |

| Faulty Spark Plugs | Ignition problems | Replace spark plugs |

| Low Coolant Level | Engine overheating | Check and top up coolant |

| Weak Battery | Electrical issues | Test and replace battery |

Hydraulic System Issues

Amidst the common hydraulic system problems experienced with the John Deere 3010, one notable issue often arises with the hydraulic fluid overheating during extended use. When the hydraulic fluid heats up excessively, it can lead to decreased system efficiency and potential damage to components.

To tackle this issue, begin by verifying the hydraulic fluid level and quality. Confirm that the fluid is at the correct level and free from contaminants. Consider using a high-quality hydraulic fluid with the right viscosity to help regulate temperature better.

Another common problem in the hydraulic system of the John Deere 3010 is leaks. Leaks can occur at various points such as hoses, fittings, or seals. Regularly inspect the system for any signs of leakage and promptly address them to prevent further damage. Additionally, check the hydraulic filter for clogs or dirt accumulation, as this can also contribute to overheating issues.

Transmission Challenges

If you’re experiencing shifting difficulties with your John Deere 3010, it could be due to issues with the transmission. Gear slippage is a common problem that can be resolved by adjusting the clutch or replacing worn-out parts.

Make sure to address these transmission challenges promptly to guarantee smooth operation of your tractor.

Shifting Difficulties

Experiencing trouble shifting gears on your John Deere 3010 may indicate underlying transmission challenges. Shifting difficulties can be frustrating, but understanding some common causes and fixes can help you get back to work quickly. Here are some possible reasons for shifting issues and their solutions:

| Issue | Solution |

|---|---|

| Stiff or Unresponsive Gear Shift | Check and replace worn shift linkage components such as bushings or pins. Lubricate the linkage to guarantee smooth operation. |

| Grinding Noise When Shifting | Inspect the clutch adjustment and adjust if necessary. Worn synchronizers may require replacement. |

| Gear Slips Out of Position | Examine the detent ball and spring for wear. Replace if damaged. Adjust the shift linkage to ensure proper engagement. |

| Difficulty Engaging Specific Gears | Verify the transmission fluid level is correct. Adjust the clutch pedal free play to allow for full disengagement. |

Gear Slippage Fix

To address gear slippage in your John Deere 3010, start by inspecting the detent ball and spring for signs of wear and consider adjusting the shift linkage for proper engagement. The detent ball and spring are vital components that help to keep the transmission gears in place. If these parts show wear or damage, they may not be able to hold the gears securely, leading to slippage. Replacing these components if necessary can improve the gear engagement.

Additionally, adjusting the shift linkage can also help resolve gear slippage issues. Ensuring that the shift linkage is correctly aligned and adjusted will promote smooth and precise gear changes. Misaligned or loose shift linkage can cause gears to slip out of place during operation.

By making the necessary adjustments to the shift linkage, you can enhance the overall performance of your John Deere 3010’s transmission system and prevent gear slippage from occurring.

Remember to perform regular maintenance checks to keep your transmission running smoothly.

Electrical Failures

Common electrical failures in the John Deere 3010 tractor often stem from issues with the wiring harness and connections. When encountering electrical problems, it’s important to first inspect the wiring harness for any signs of wear, corrosion, or damage. Over time, the wiring insulation can deteriorate, leading to short circuits or open circuits that disrupt the flow of electricity. Make sure that all connections are secure and free of debris, as loose or dirty connections can cause intermittent electrical issues.

Another common source of electrical failures in the John Deere 3010 is the voltage regulator. A faulty voltage regulator can result in overcharging or undercharging of the electrical system, leading to battery drain or damage to electrical components. If you suspect a voltage regulator issue, it’s recommended to test the regulator’s output using a multimeter to determine if it’s functioning within the specified range.

Starter Problems

When troubleshooting starter problems in the John Deere 3010 tractor, begin by checking the battery connections and condition for optimal performance. Confirm the battery terminals are clean and tight to guarantee a good electrical connection. If the connections are corroded or loose, it can lead to starting issues.

Next, examine the starter solenoid for any signs of wear or damage. The solenoid plays a vital role in engaging the starter motor when you turn the key. If the solenoid is faulty, it may not transmit the necessary electrical current to start the engine.

Additionally, inspect the starter motor itself. Look for any visible damage, such as frayed wires or worn-out components. If the starter motor isn’t functioning correctly, it will struggle to turn over the engine. Sometimes tapping the starter motor lightly with a hammer can temporarily fix a stuck motor.

Fuel System Concerns

Check the fuel lines and filters regularly to prevent potential issues with the fuel system in your John Deere 3010 tractor. Proper maintenance of the fuel system is important for peak performance. Inspect the fuel lines for any signs of wear, cracks, or leaks. Replace any damaged lines immediately to prevent fuel leakage and maintain a consistent flow of fuel to the engine.

Regularly changing the fuel filters is essential to prevent contaminants from entering the fuel system. Clogged filters can restrict fuel flow and lead to engine stalling or reduced power output. Follow the manufacturer’s recommendations for filter replacement intervals to maintain the efficiency of your tractor’s fuel system.

In addition to inspecting the fuel lines and filters, it’s important to monitor the fuel quality. Use clean, high-quality fuel to prevent sediment buildup in the fuel tank and lines. Contaminated fuel can cause blockages and damage fuel system components.

Steering Malfunctions

Inspect the steering components regularly for wear and proper functionality to prevent potential steering malfunctions in your John Deere 3010 tractor. The steering system is vital for safe and efficient operation, so keeping it in top condition is essential. Here are some common steering issues you may encounter with your John Deere 3010 and their possible fixes:

| Steering Issue | Possible Fix |

|---|---|

| Excessive play in the steering wheel | Check and adjust the steering gear mesh. |

| Hard steering | Inspect the power steering pump and fluid levels. |

| Steering wheel vibration | Check for tire issues or wheel balance problems. |

| Uneven steering effort | Inspect the steering column and connections. |

| Steering wheel not returning to center | Check the steering linkage for binding. |

User Complaints

Document user complaints meticulously to identify recurring issues and trends in the performance of your John Deere 3010 tractor. Understanding common grievances can help you proactively address potential problems and keep your tractor running smoothly.

Here are some typical user complaints to look out for:

- Engine Overheating: Users might report issues with the engine overheating, which could stem from cooling system malfunctions or inadequate maintenance. Regularly check coolant levels and maintain proper airflow around the engine to prevent overheating.

- Transmission Slipping: Complaints about the transmission slipping or difficulty shifting gears could indicate low transmission fluid levels, worn-out clutch components, or other transmission-related issues. Promptly addressing these complaints can prevent further damage to the transmission system.

- Electrical Failures: Users may encounter electrical problems such as issues with the starter, lights, or gauges not functioning correctly. Inspect the wiring harness, battery connections, and electrical components to troubleshoot and resolve these complaints effectively.

Frequently Asked Questions

Can the John Deere 3010 Be Easily Converted to Run on Biodiesel?

Sure, converting a John Deere 3010 to run on biodiesel is feasible. It involves modifying the fuel system to handle the different properties of biodiesel.

Key steps include:

- Upgrading seals and hoses

- Adjusting the fuel injection timing

- Possibly installing a heated fuel system for cold weather operation

Remember to consult with a mechanic familiar with biodiesel conversions to guarantee proper installation and performance.

Are There Any Common Issues With the PTO System on the 3010?

When it comes to the PTO system on the 3010, you might encounter some wear and tear issues over time. Keep an eye out for potential slipping or malfunctioning of the PTO clutch.

Regular maintenance and inspections can help prevent these common problems. If you notice any unusual noises or decreased performance, it’s best to address them promptly to avoid more significant repairs down the line.

What Are Some Recommended Aftermarket Upgrades for the John Deere 3010?

Looking to give your John Deere 3010 a boost? Consider upgrading to an electronic ignition system for improved performance.

Adding a power steering kit can make maneuvering easier, while installing a new seat for comfort during long hours of operation is a smart move.

Upgrading to LED lights enhances visibility, and a hydraulic remote kit can increase the versatility of your tractor.

These aftermarket upgrades can enhance your overall experience with the 3010.

How Often Should the Tires on a John Deere 3010 Be Replaced?

You should replace the tires on your John Deere 3010 based on wear and tear. Inspect them regularly for tread depth, signs of damage, and overall condition. Factors like usage, terrain, and maintenance affect tire lifespan.

As a general guideline, replacing tires every 3-5 years is common. However, individual circumstances may vary, so monitor your tires closely and replace them promptly when needed to guarantee peak performance and safety.

Is It Possible to Install a Cab on a John Deere 3010 Tractor?

Yes, it’s possible to install a cab on a John Deere 3010 tractor. A cab can provide protection from the elements, reduce noise levels, and improve comfort during long work hours.

To install a cab, make sure compatibility with your tractor model, follow manufacturer instructions, and consider professional assistance for a proper fit.

Cabs can enhance operator experience and productivity by creating a more comfortable working environment.

Conclusion

Just like a well-tuned tractor needs regular maintenance to keep running smoothly, our own lives require care and attention to guarantee peak performance.

By addressing common issues with the John Deere 3010, we can learn to proactively handle challenges in both our machinery and our daily lives.

Remember, prevention is key to avoiding breakdowns and maintaining a strong foundation for success.

Keep on top of maintenance tasks, and you’ll be ready to tackle any obstacle that comes your way.

Last updated on September 6, 2025